Wine Barrel

Maintaining Humidity Levels for Production Quality and Repeatability

By humidifying barrel storage rooms, MeeFog drastically reduces the need for topping off barrels during the aging process and aids in maintaining the aging profile for repeatability.

Benefits:

- Reduces topping.

- Uniform humidity distribution.

- Precise control.

- Ultra-fine fog droplets – no wetting.

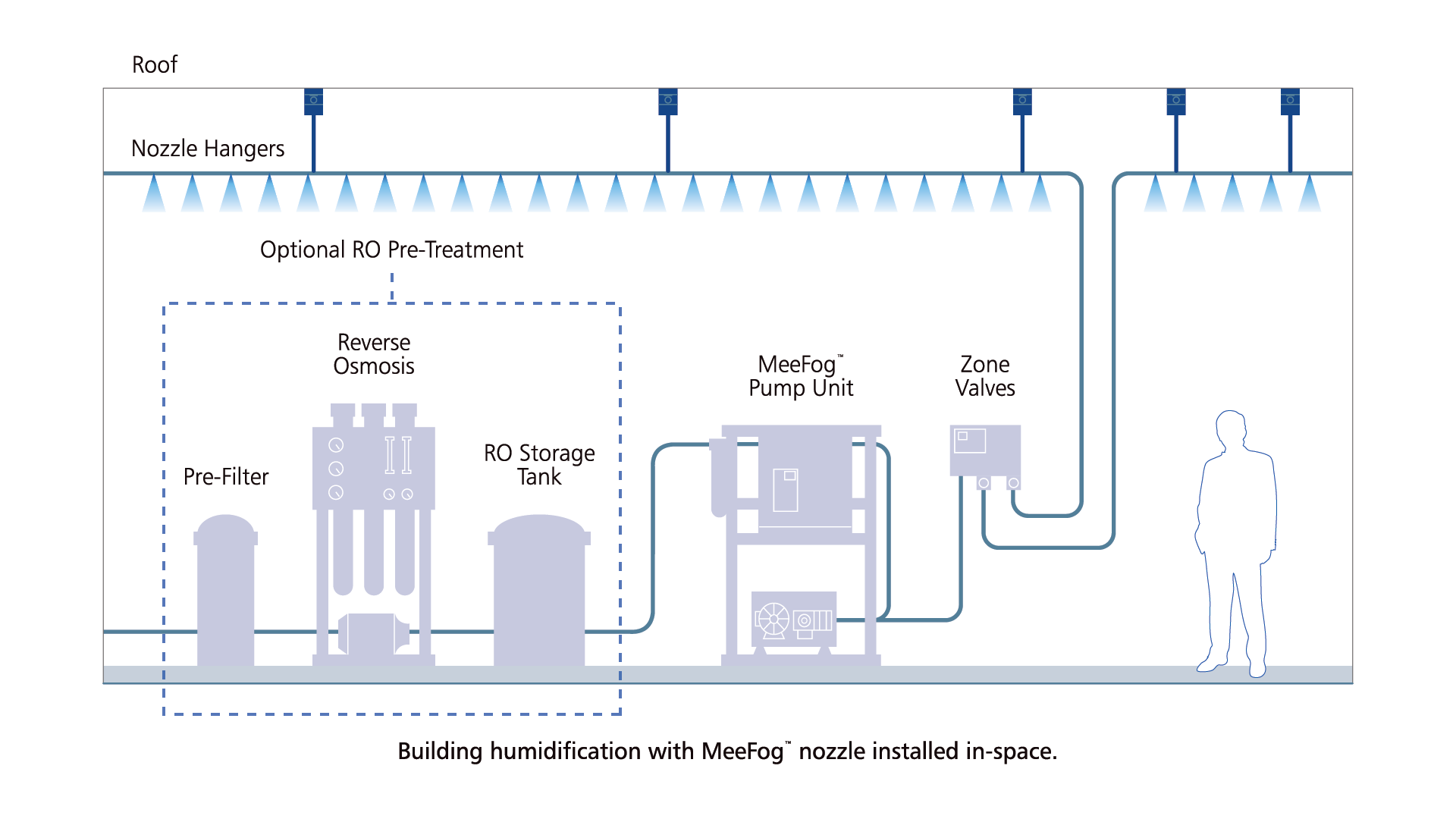

MeeFog In-Space Installation Diagram

Click the different areas of the diagram below to learn more information about our system.

Water Pre-Treatment

Water Pre-Treatment

Basic water treatment, namely, a water softener is required for mineral removal. Based on dust-free requirements for the space additional components including reverse osmosis with automated membrane flushing and pre-treatment filtration can be added.

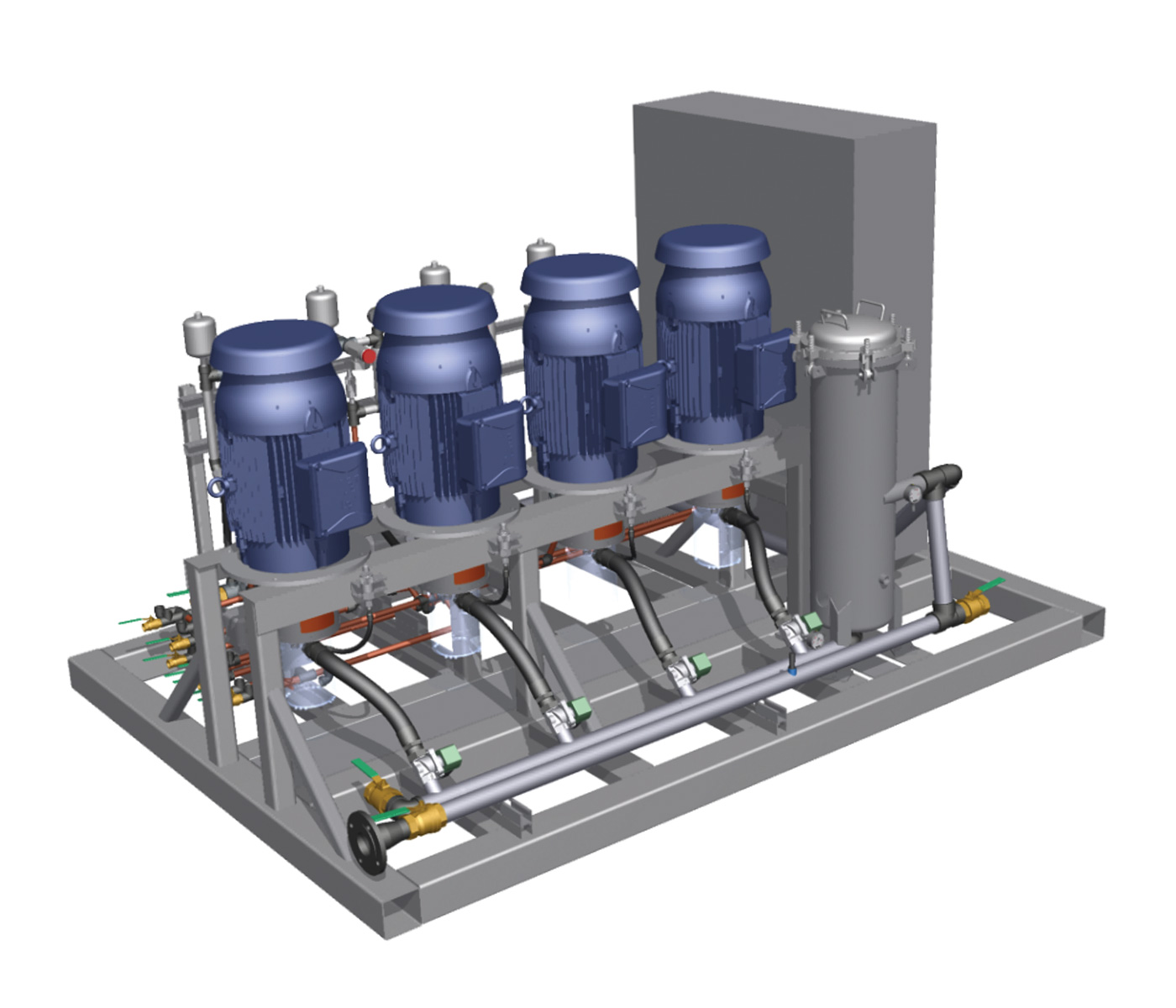

MeeFog Pump

MeeFog Pump

The high-pressure pump maintains 1000 psi water pressure in order to atomize the water into tiny droplets that can evaporate overhead. The pump rack has a VFD with panel-mounted controller that maintains pressure when zone valves open and close.

Zone Valve Panel

Zone Valve Panel

The MeeFog Zone Valve Panel provides control for up to five fogging zones. It can use an on-board humidity sensor or signal from other controllers to actuate ball valves that are slow acting to eliminate water hammer.

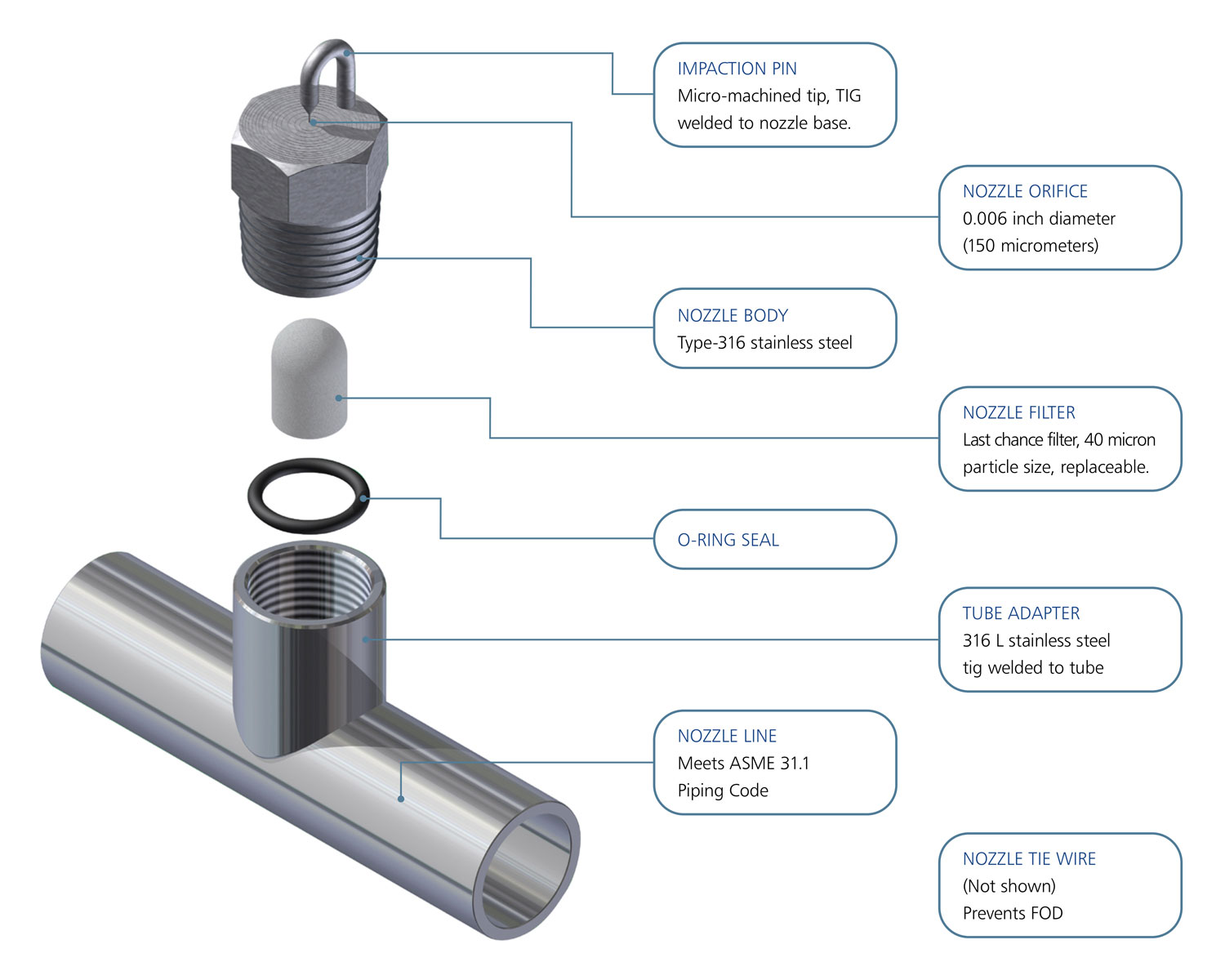

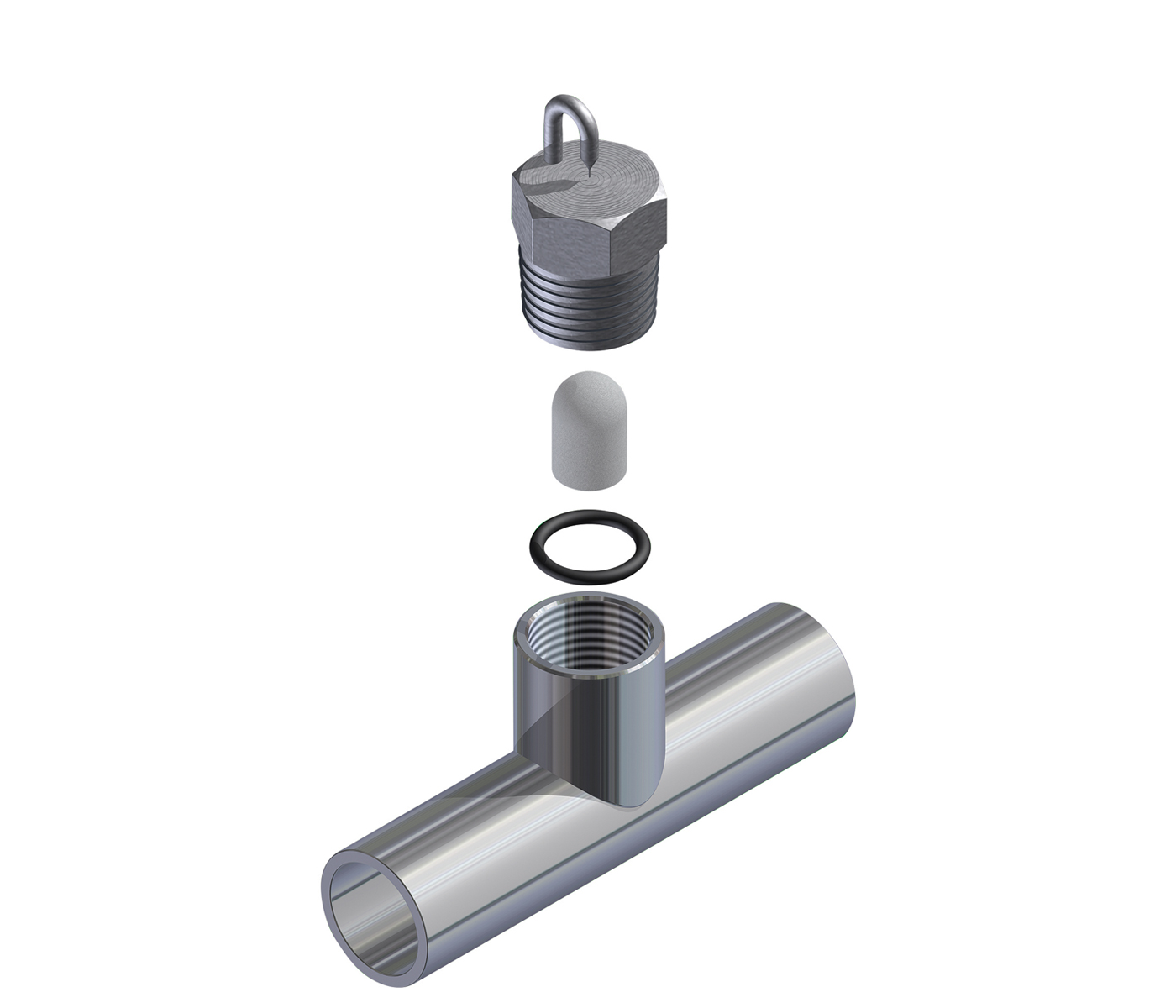

Swirl Jet Nozzles

Swirl Jet Nozzles

The MeeFog Swirl Jet nozzles are stainless steel with a .006” orifice and output 7 lbs. per hour of fog. Fog nozzles mounted on stainless steel tubing can be spaced one per 200 square feet or denser for areas with open bay doors or in need of higher humidity.

System Overview

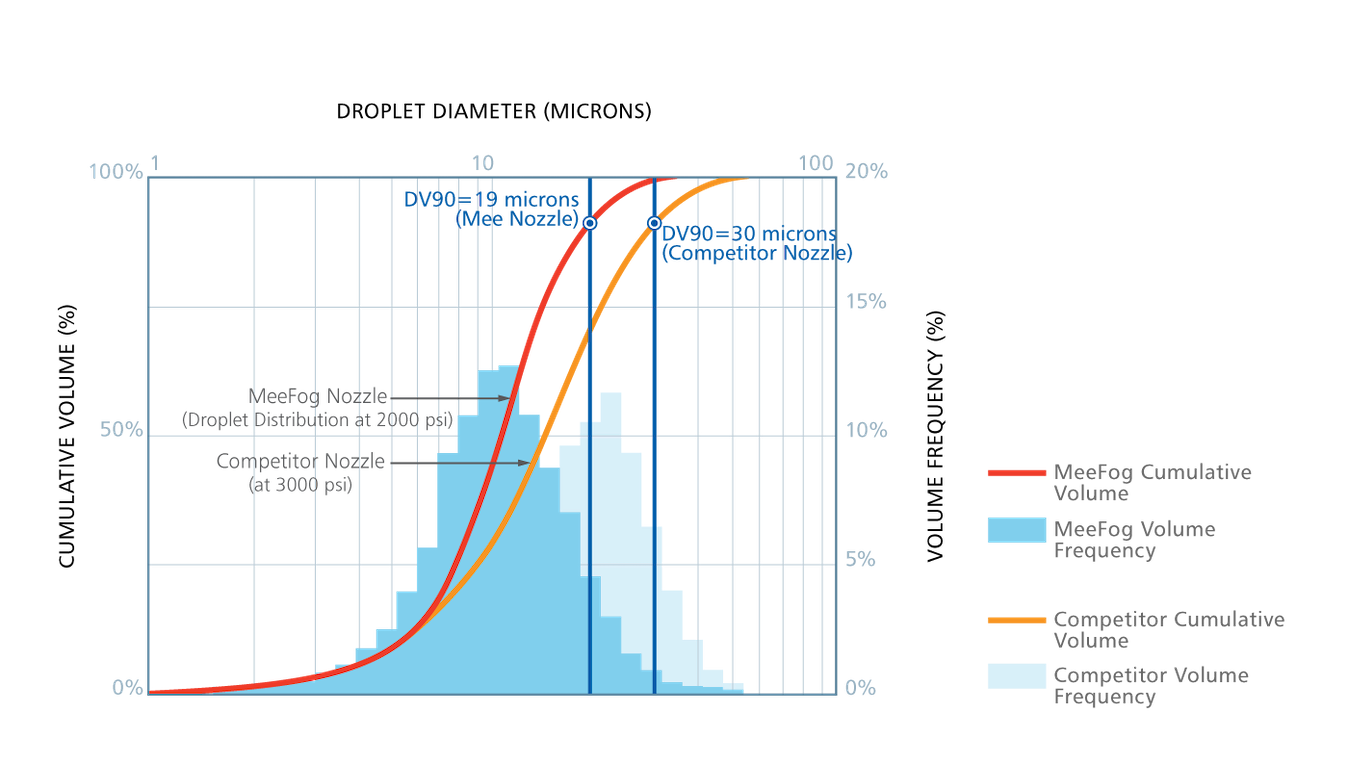

Nozzle Comparison

At an operating pressure of 2000 psi, the resulting average droplet size is roughly one tenth the diameter of a single strand of human hair.

MeeFog System Benefits

- Compressor not required.

- Quiet operation.

- Reduces topping.

- Uniform humidity distribution.

- Precise control.

- Ultra-fine fog droplets – no wetting.

- Flexible and easy to retrofit.

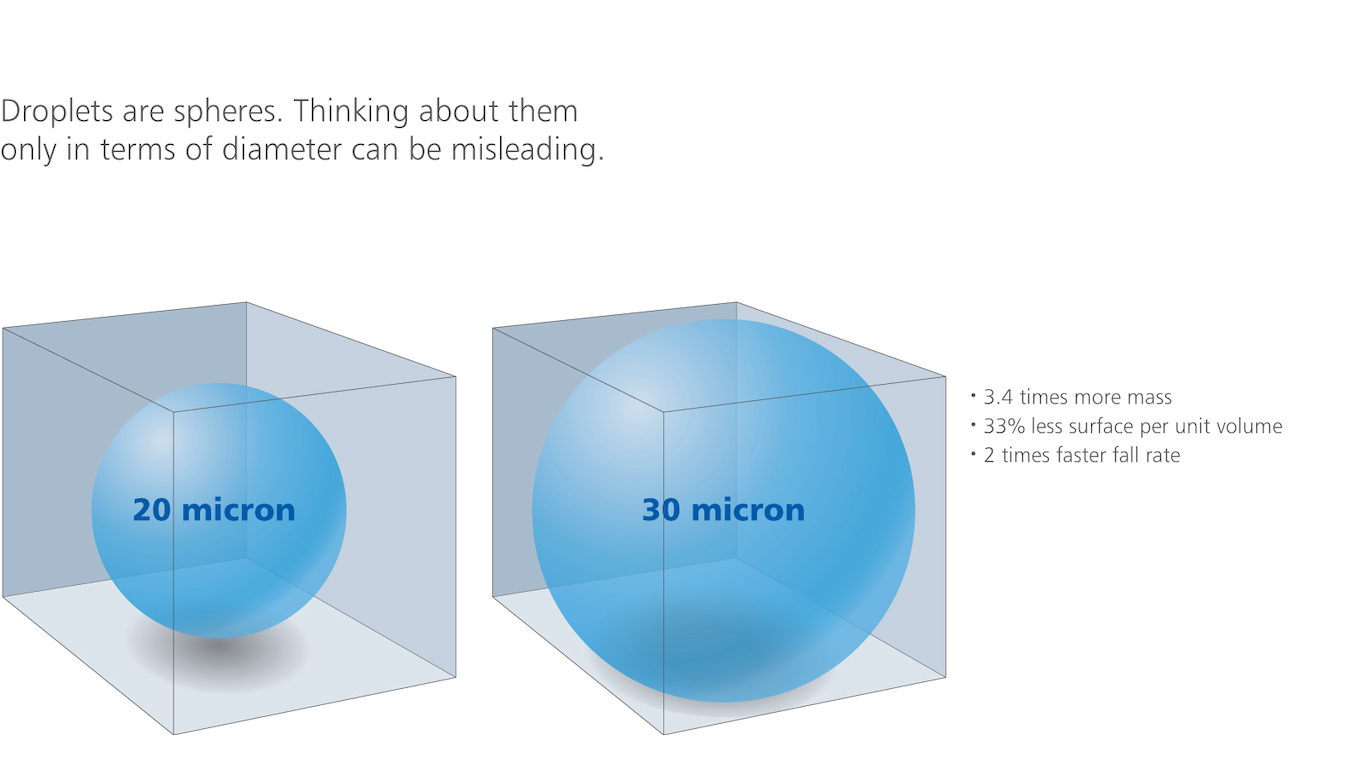

Droplet Comparison

Small droplets have a larger surface to volume ratio compared to larger droplets. This allows them to evaporate much more rapidly than larger droplets.

Want Proof?

We’ll gladly supply a detailed payback analysis report for your existing Wine Barrel including:

- Installed MeeFog system cost.

- Predicted process expenses per year.

Featured Case Study

Jamieson Ranch Vineyards Saves

on Topping Costs by Improving Humidification

The Challenge:

With a lack of space on site, Jamieson Ranch Vineyards’ rapid expansion forced it to convert an old bottling facility into a barrel room. By doing so, it had to address low humidity in the new space. This led to barrels drying out during the ageing process and too much wine evaporating.

The Solution:

Adding a MeeFog humidification system kept empty barrels from drying out and greatly reduced the need for topping due to evaporative losses. In addition, the state-of- the-art MeeFog system slashed maintenance and energy costs compared to older humidification systems the company employs in its other barrel rooms.

Jamieson Ranch Vineyards decided to convert an old bottling facility into a barrel room to house their rapid expansion. Low humidity in the new space caused barrels to dry out during the aging process which led to excessive wine evaporation.

“The MeeFog system has reduced topping and keeps our barrels tighter by maintaining humidity at 80%. In addition, our empty barrels no longer dry out which helps maintain their integrity.”

– John Maguire – Cellar Master of Jamieson Ranch Vineyards