Heat Exchanger Pre-Cooling Systems

Fast Return on Investment from Energy Savings

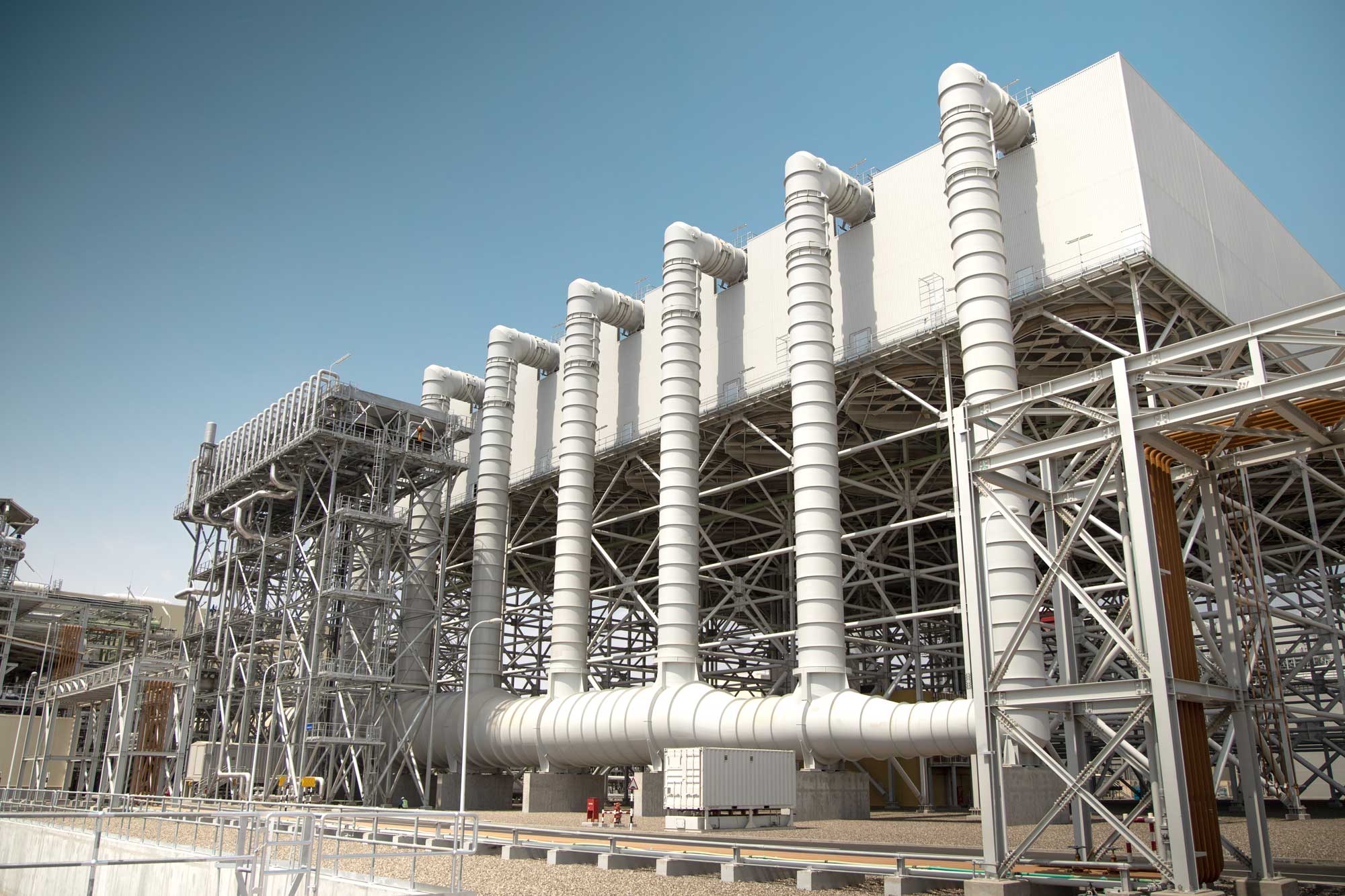

Heat Exchanger Pre-Cooling That Boosts Capacity in Hot Weather

MeeFog uses high-pressure water fog to cool the air entering heat exchangers. Most droplets evaporate before reaching the coils, lowering inlet air temperature so your equipment can reject heat more efficiently, in hot conditions (often ~20°F of inlet air cooling or more, depending on climate).

Benefits:

- Increase cooling capacity in hot conditions (often ~20°F of inlet air cooling or more, depending on climate)

- Improve heat rejection and help stabilize performance during peak temperatures

- Reduce energy use in condenser/chiller applications (brochure notes 30%+ chiller load reduction in some installs)

- Designed to minimize over-wetting and water drip-back

Performance Protection for Hot Weather

Challenge

When ambient temperatures rise, air-cooled equipment struggles to reject heat, leading to higher energy costs, reduced performance, or even equipment failure.

Solution

Result

Equipment performs as if 80°F on 100°F days – heat is rejected more efficiently, reliability improves, and chiller electrical load drops 30%+.

How fog pre-cooling works

Heat exchanger pre-cooling injects atomized water (fog) into the inlet airflow. As the droplets evaporate, they absorb heat from the air—creating an evaporative cooling effect before the air reaches the coils. Any remaining droplets are intended to evaporate from the fins without excessive runoff.

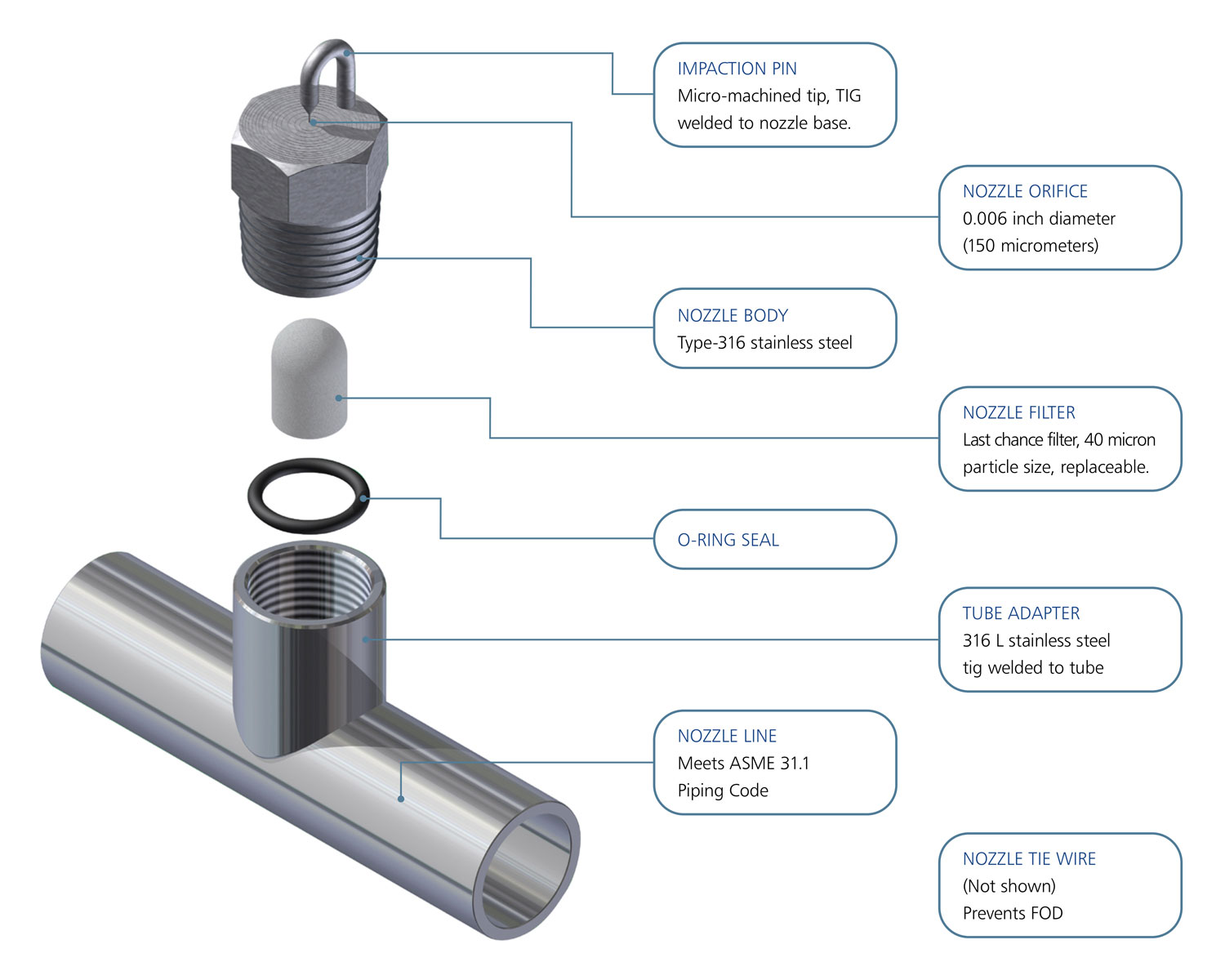

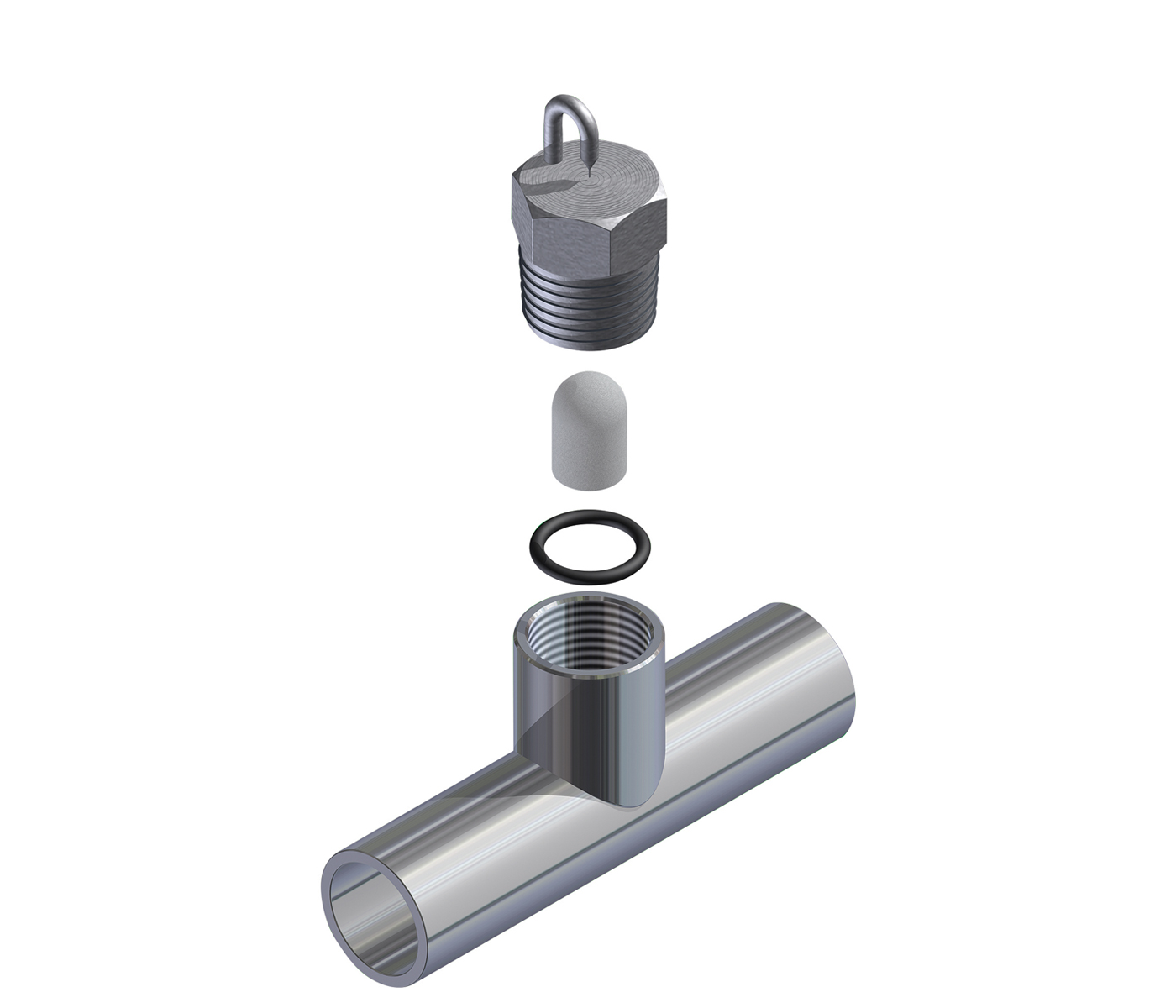

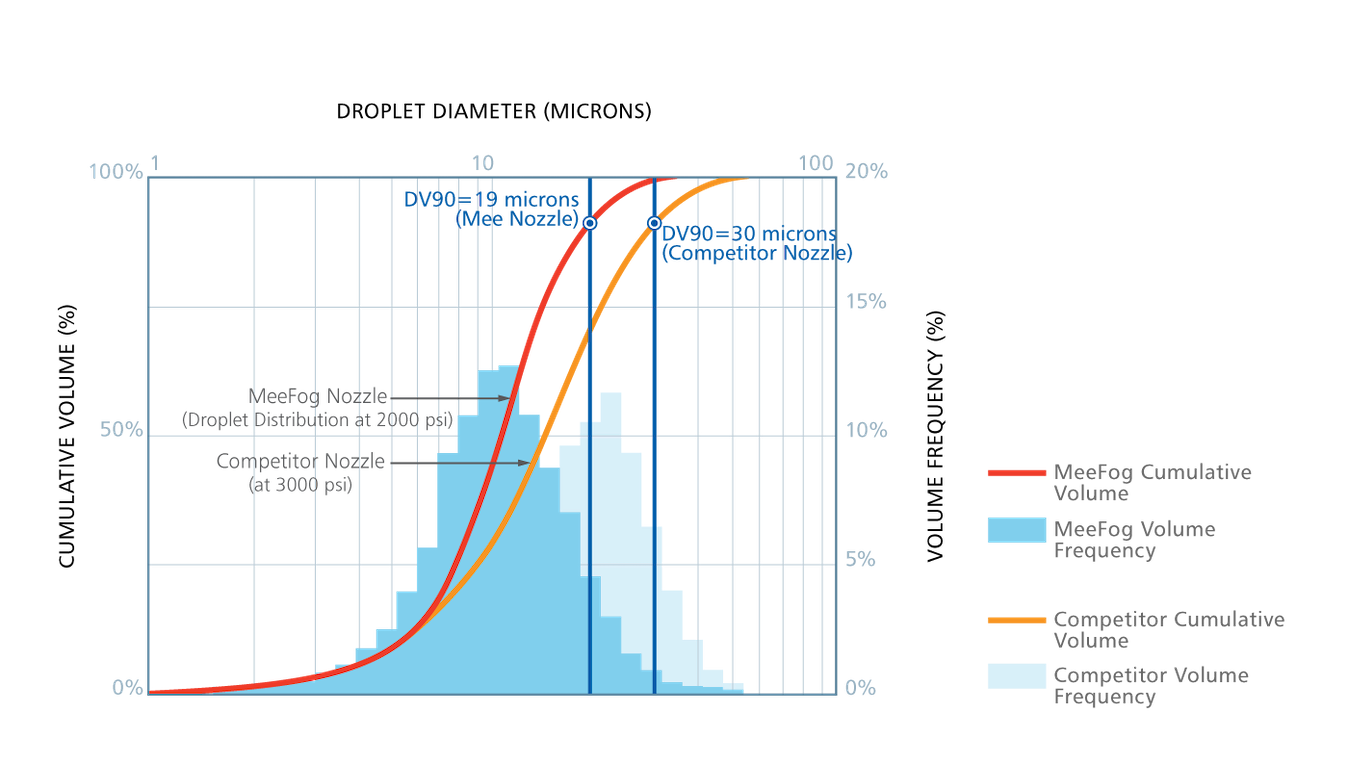

MeeFog utilizes proprietary nozzle technology that produce micro-fine droplets smaller than 10 microns (1/10th the width of a human hair).

- Flash Evaporation: Water evaporates quickly in the airstream.

- Zero Wetting: No rain-back on the ground and no mineral buildup on coils when using treated water.

- Equipment Safety: Nozzles are strategically placed to avoid electrical parts and fan belts.

System Overview

Nozzle Comparison

At an operating pressure of 2000 psi, the resulting average droplet size is roughly one tenth the diameter of a single strand of human hair.

MeeFog System Benefits

- Increase heat rejection from existing units.

- Increases refrigeration capacity.

- Cools and conditions.

- Easy to service and maintain.

- Ultra-fine fog droplets.

- Stainless steel construction.

- Flexible and easy to retrofit.

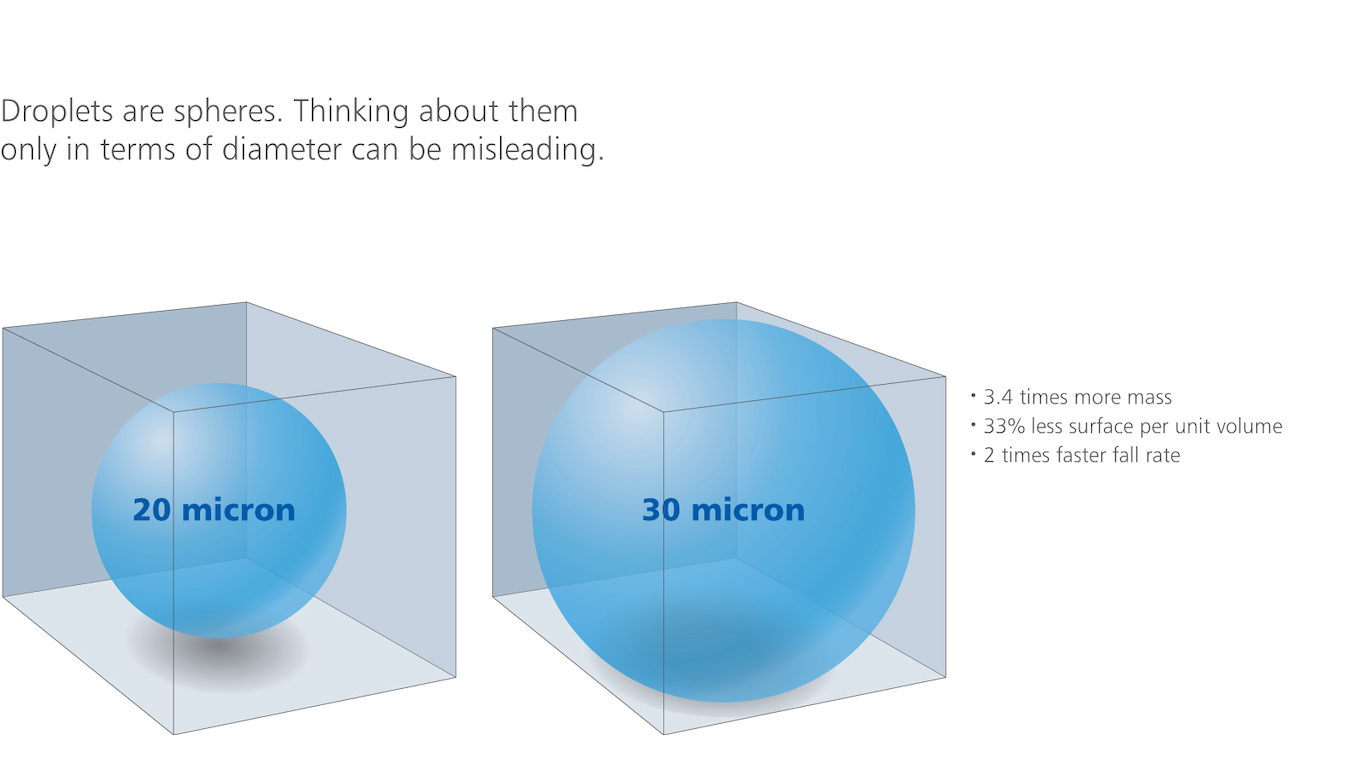

Droplet Comparison

Small droplets have a larger surface to volume ratio compared to larger droplets. This allows them to evaporate much more rapidly than larger droplets.

Want Proof?

We’ll gladly supply a detailed payback analysis report including:

- Installed MeeFog system cost.

- Guaranteed power gain.

- Predicted process gains per year.

Heat Exchanger Pre-Cooling FAQ

Heat exchanger pre-cooling consists of cooling the air flowing to the heat exchangers to improve their performance on a hot day. MeeFog systems atomize water to create a fog of liquid water droplets that evaporate and cool the air.

On a hot afternoon it’s possible to cool by 30°F (17°C) or more in an arid climate, at least 20°F (11°C) in a temperate climate, and at least 10°F (5.6°C) in a tropical climate.

Evaporatively cooling the airflow to an air cooled condenser allows the condenser to release heat more effectively which makes the chiller more effective on a hot day.

Fog systems can be designed to provide several stages of cooling. For instance, a system capable of 10 °F of cooling can be designed with two cooling stages of 5 °F each. This allows the operator to do only as much cooling as is needed, thereby conserving water usage.

Small droplets are important because they expose more of the water’s surface to the surrounding air. Water only evaporates from the surface, so exposing more surface area means the air can be cooled faster and less water drips off the heat exchanger. Dripping water is lost to the evaporative cooling process, so minimizing it saves water and ensures maximum cooling for a given water flow rate.

Yes. MeeFog systems can be easily retrofit to existing air-cooled heat exchangers.

The water should have low levels of calcium and magnesium since these minerals can form a hard scale that is difficult to remove from the heat exchanger fins. Mee Industries can help design a water treatment system that will ensure long life and minimal maintenance.

MeeFog systems can be controlled based on ambient temperature. For example, for a system with two stages, the first stage can be turned on when the ambient temperature exceeds 85°F (30°C), and the second stage can be turned on when the ambient temperature exceeds 90°F (32°C). The temperatures at which fog stages operate can be selected based on climate data and process requirements. MeeFog systems can also be controlled based on the temperature of the cooled fluid when it leaves the heat exchanger.

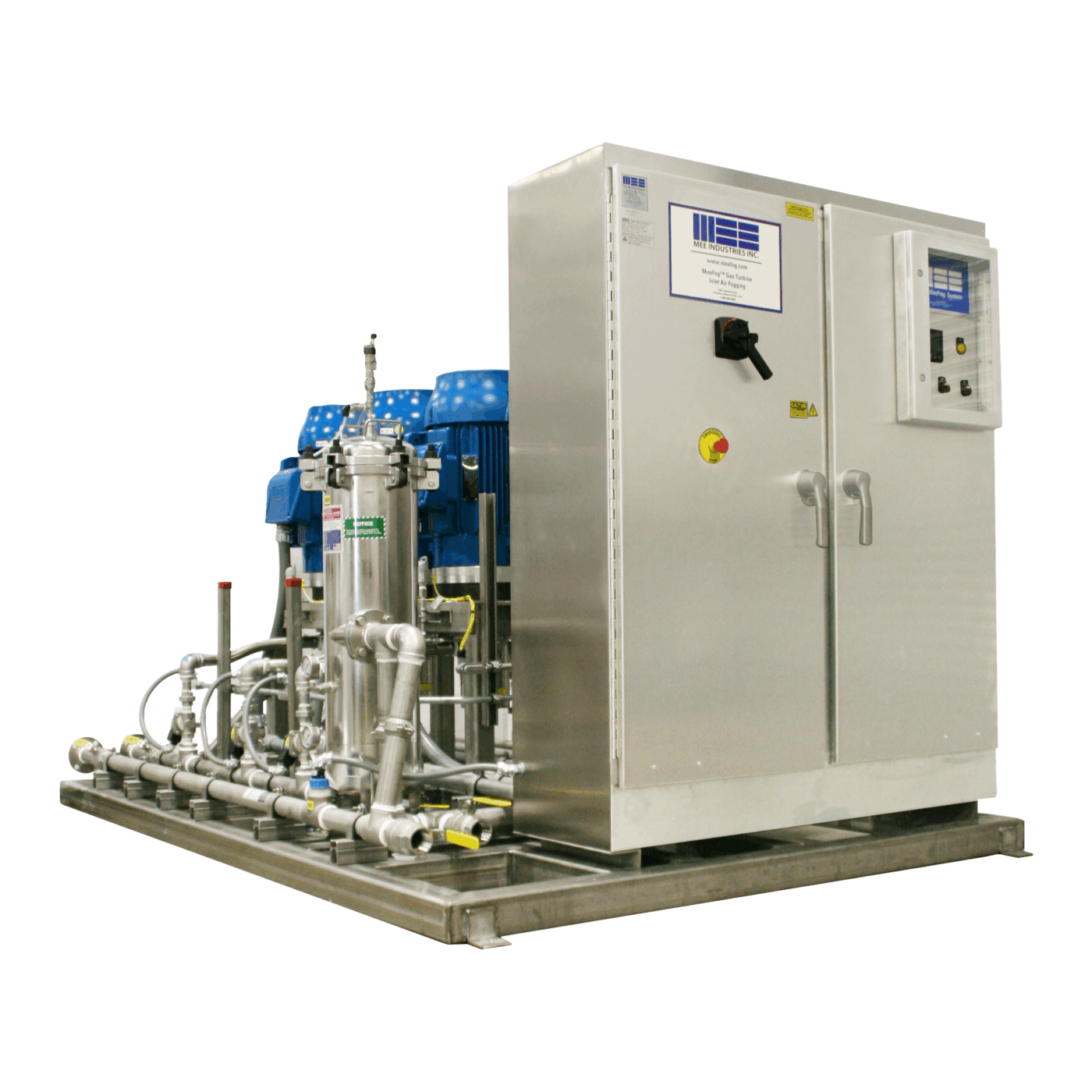

Fog systems require very little maintenance. Inlet water filters need to be changed periodically, and any water treatment equipment will need regular service. The high-pressure pumps are water-lubricated, multi-stage centrifugal pumps that can operate for many years with very little maintenance.

MeeFog systems can operate for more than 30 years with proper maintenance. The fog nozzles themselves do not wear out and can be used for the life of the system, assuming water treatment is maintained.

Water fallout is reduced or eliminated by using many fog nozzles with flow rates that are low enough to prevent over-wetting of the coils. Overspray can provide more cooling than would be possible from just evaporatively cooling the inlet air because water can be evaporated off the hot coils themselves.

Fog nozzles, fog nozzle lines, feedlines, and pumps are all stainless steel, which ensures long life and minimal maintenance.

Typical lead-times are 12 weeks for smaller projects and 24 weeks for larger projects. The MeeFog pump skids are typically fully assembled. MeeFog factory installs the fog nozzles in the nozzle lines and conducts factory testing. Nozzle lines typically ship in 20-foot sections. Installation consists of bolting the pump skid to a foundation and installing the feedlines and nozzle lines. Mee Industries provides all drawings and a technical advisor for the installation.

Yes. You can view MeeFog case studies for several installations on steam condensers, AC condensers, etc. at this link on our website. (link here https://www.meefog.com/category/our-solutions/fog-cooling-for-gas-turbines-heat-exchangers/heat-exchanger-pre-cooling/ )

MeeFog systems can be used whenever the temperature is above freezing. It is usually possible to cool by at least 10°F (5.5°C) even on humid afternoons in a tropical climate.

Mee Industries regularly guarantees the amount of cooling a system will produce on a hot day. MeeFog systems have a 12-month warranty. Longer warranty terms are available on request.

Featured Case Study

New York City Financial Institution

Data Center Heat Rejection on Rooftop

System Design:

The MeeFog system for this application consisted of a single 10 hp, 480V Grundfos CRI-5 pump with Allen Bradley controllers to pressurize the water for use by the eight original condensers. 3/4″ stainless steel feedlines bring the water from the pump to the 90-nozzle fogging arrays placed in the bottom inlet of the condensers.

Installation Challenges/Specifications:

To keep the data center operating, since there was no room for additional rooftop condensers, the financial institution needed to find a way to get more cooling out of the condensers it did have by bringing down the inlet air temperature. After experimenting with lawn water sprinklers to spray water into the inlet air on the bottom of the condensers, IT decided to put in a more efficient and controllable MeeFog system to keep the glycol temperature and pressure within limits.