MeeFog System Boosts Air Compressor Output at Fertilizer Plant

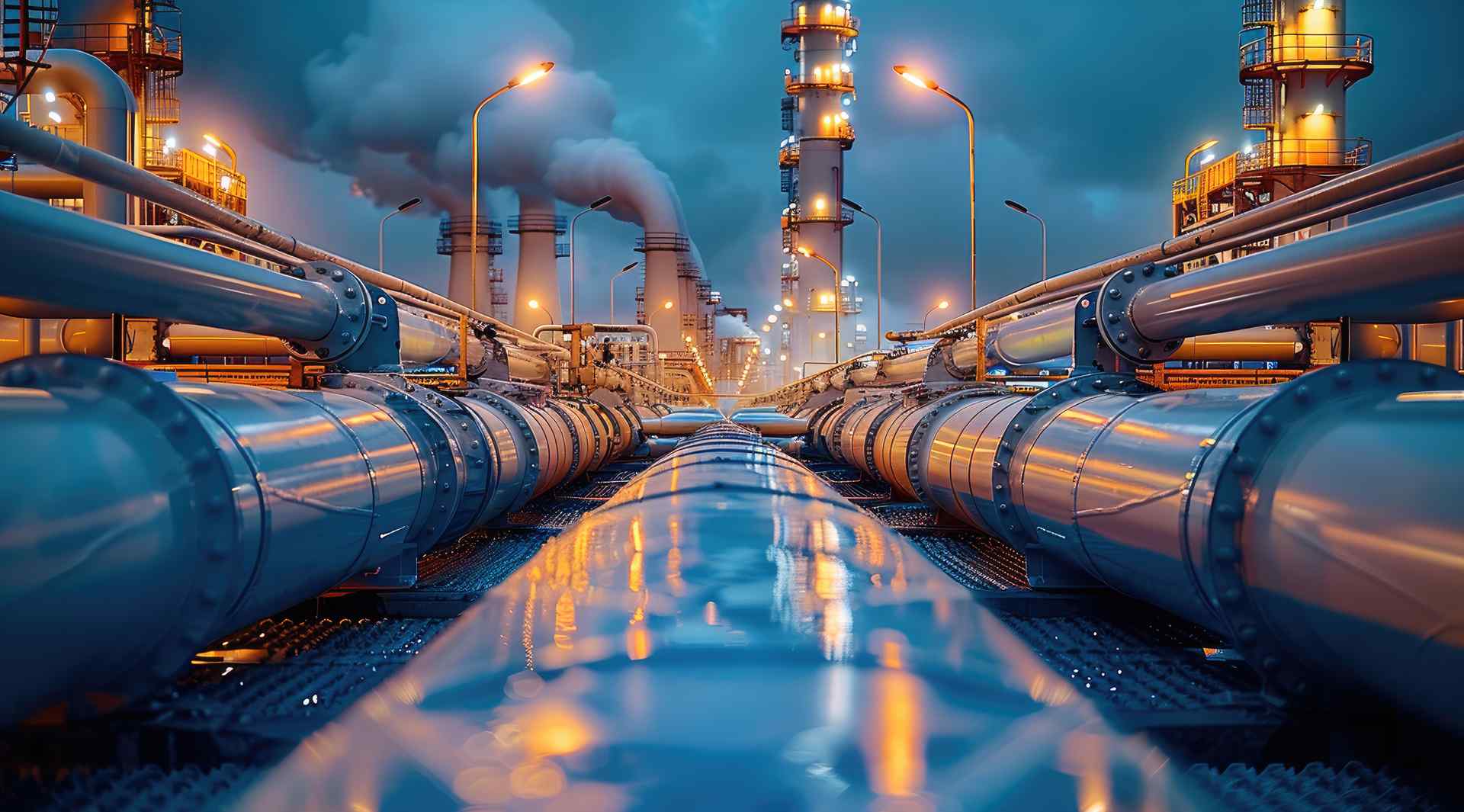

Heat Exchanger Pre-Cooling

Optimizing Ammonia Production with MeeFog Technology at Simplot’s Helm Fertilizer Plant

Location: Helm, California, USA

Industry: Agriculture and Fertilizer Production

J.R. Simplot is a family-owned and privately held food and agriculture company headquartered in Boise, Idaho. As one of the largest privately held food and agribusiness companies in the nation, its portfolio includes food processing and food brands, phosphate mining, fertilizer manufacturing, farming, ranching and cattle production, and other enterprises related to agriculture. It has operations in the U.S., Canada, Mexico, Argentina, Australia, and China. J.R. Simplot’s fertilizer plant in Helm, CA is one of its major U.S. production facilities. It sits in the heart of California’s San Joaquin Valley. The area experiences hot dry summers yet also faces freezing temperatures in winter. Humidity levels are generally low, but there can be periods of high summer humidity.

The Challenge:

During California’s intense summer months, Simplot’s Helm fertilizer plant faced significant drops in production at the very time when demand was at its peak. The facility needed a solution that would boost output and while lowering energy consumption as part of ongoing sustainability efforts.

The Solution:

Implementation of the MeeFog system, which reduced inlet air temperatures by up to 30°F. This adaptation was critical in boosting the efficiency and output of the air compressor used in ammonia production, which is vital during high-demand periods.

The Installation:

The MeeFog system comprises eight stages of cooling. Each cooling stages has seven fog nozzles for a total of 1.8 gallons per minute of water. The water is converted into micro-fine droplets by Mee’s patented impaction pin nozzle. These nozzles are designed to prevent the formation of large droplets and to ensure that droplet sizes are maintained below 20 microns.

Fog System Benefits at Helm, CA:

The MeeFog system at the J.R. Simplot fertilizer plant in Helm, CA has been operating since 2007, more than 15 years. Initial costs were recouped over the first couple

of summers due to a significant increase in ammonia production. As maintenance work is nominal, the system has paid for itself many times over.

The Benefits of MeeFog Technology:

- Up to 10% power boost during the hot summer months.

- The facility earned an Energy Star rating from the EPA for the past four years.

- Energy production at the plant has been reduced by 25% over the past decade due to a series of upgrades and modifications.

“Running the MeeFog system during the summer months results in about 5 to 10% increase in production compared to running without.”

-Agus Sumantri, Engineer and Production Manager at J.R. Simplot