Instant 1 MW Power Boost for Offshore Gas Re-Injection Well

Fog Cooling For Gas Turbines & Heat Exchangers

Reliable Performance of Inlet Air Cooling for Offshore Gas Turbines

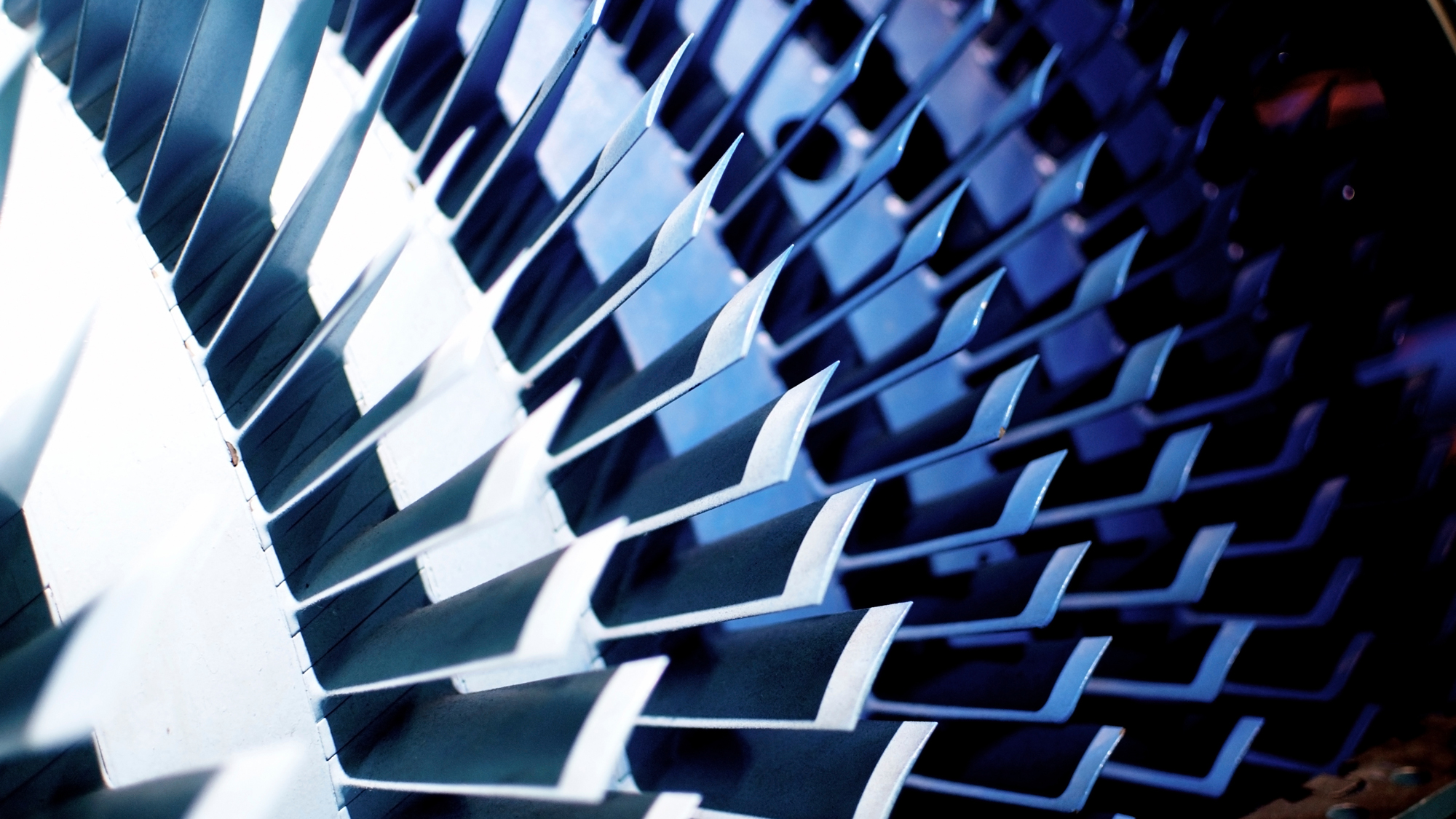

An offshore gas re-injection well in the Persian Gulf needed to maintain high levels of productivity despite challenging environmental conditions, where temperatures often soared to 93°F (34°C). The high ambient temperatures were reducing the power output of the gas turbine, leading to decreased efficiency in gas compression. Mee Industries provided an advanced inlet air cooling system for offshore gas turbines– specifically designed to operate under these harsh conditions. The system was installed on a Rolls Royce RB211G gas turbine, effectively cooling the inlet air by up to 25°F (14°C) and delivering a power boost of 1 MW. This inlet air cooling for offshore gas turbines system allowed the well to maintain high efficiency, even during the hottest months.

MeeFog’s Inlet Air Cooling System Implementation:

Developed a seven-stage fogging system to lower inlet air temperatures by 25°F (14°C) for an offshore platform operating at 2,000 psi with 8-micron fog droplet sizes. Provided the fog pump skid and nozzle manifolds and oversaw the installation and commissioning to ensure the system was fully operational and optimized for the environment. After 25,000 hours of operation, the system was tested during the extreme climate conditions from May through July. The results showed a significant improvement, with an additional six to seven MMSCFD (million standard cubic feet per day) of gas being pumped using the MeeFog™ system.

Measurable Outcomes:

- Power Boost: The MeeFog system delivered a power boost of 1 MW, which was crucial for maintaining productivity during peak temperature periods.

- Increased Gas Compression: The system enabled the pumping of an additional six to seven MMSCFD of gas, significantly enhancing the well’s output.

- Efficiency: The cooling system operated efficiently with a maximum water flow of 8.8 gpm and a power requirement of just 15 HP, making it an energy-efficient solution.

Project Conditions:

Location: Persian Gulf platform

Hot Day Conditions: 93°F (34°C)

Cooling Capacity: 25°F (14°C)

Max Power Boost: 1 MW

Fog Skid Design:

Cooling Stages: 7

Operating Pressure: 2,000 psi

Fog Droplet Size: 8 microns SMD

MeeFog™ Nozzle Count: 196

Nozzle Flow Rate: 0.045 gpm per nozzle

Max Water Flow: 8.8 gpm

Max Power Requirement: 15 HP

Learn More About Meefog Systems

Read about the benefits of Meefog’s Fog Cooling System from previous successful installations: