MeeFog System Enhances Air Quality and Energy Efficiency at Grand River Hospital, Ontario

Hospital & Healthcare

Grand River Hospital

Grand River Hospital (GRH) in Kitchener, Ontario, is one of the largest community hospitals in the region, providing care to over 500,000 people in Waterloo Region and Wellington County. Formed by the merger of Kitchener-Waterloo Hospital and the Freeport Health Center in 1995, GRH has 495 beds and a dedicated team of 2,500 nurses and support staff, along with 500 physicians and midwives. The hospital handles more than 23,000 patient admissions, 60,000 emergency visits, and over 200,000 ambulatory care visits annually.

Installation Challenges

One of the major issues all hospitals face is keeping patients, visitors and staff from catching new diseases. Maintaining the proper level of indoor humidity is a crucial part of this.

As the U.S. Centers for Disease Control and prevention has noted. “Low humidity may be associated with an increased susceptibility to upper respiratory infections.” If the humidification system is set too high, it leads to mold growth in the air ducts, with the spores entering the airstream.

Grand River Hospital had installed a sprayed coil system in 1988 but, in order to save energy, switched to a steam system a few years later.

This did reduce the energy usage, however it also meant that the boiler feed water additive chemicals were entering the air with the steam. The hospital, therefore looked into other forms of humidity control and found that a fogging system would not only improve the quality of the air, but even further reduce costs.

I worked on an energy balance which compared the running costs using boiler plant steam vs. fog, and it showed payback in less than one season based on the costs of steam production. – -Bill Goddall Director of Facility Redevelopment

Challenges/Specifications:

Maintaining proper indoor humidity is crucial for preventing the spread of diseases in hospitals. Low humidity can increase susceptibility to respiratory infections, while high humidity can lead to mold growth in air ducts. GRH’s existing steam humidification system introduced boiler feedwater chemicals into the air, prompting the hospital to seek a better solution for humidity control.

Solution:

MeeFog Industries designed a high-pressure fogging system tailored to the specific needs of Grand River Hospital. The system was implemented across nine air handlers with a combined airflow of 157,000 CFM. The fogging system features a main pump unit driven by a 5 HP variable frequency drive (VFD) to deliver 1000 psi water. The water is converted into minute droplets by impaction pin nozzles within each AHU, providing the necessary humidity without introducing contaminants.

The Installation:

The Meefog system consists of one main pump unit driven by a 5 HP variable frequency drive (VFD) to provide the fogging system with 1000 psi water. Within the inlet duct for each of the AHUs are two or three individually controllable arrays of impaction pin nozzles that convert that 1000 psi water into a fog of minute droplets (about 10 microns diameter) which quickly evaporate to provide the required humidity. Altogether, the system has 20 stages of humidification control and can add up to 1704 pounds of water per hour to the air.

While Meefog systems can operate off their own sensors and programmable logic controllers (PLCs), in this case, it is controlled by the hospital’s existing Delta Controls Energy Management Control System (EMCS). Sensors were installed in each GRH zone being serviced, with additional sensors to measure the return air humidity. When the EMCS detects that the air in a zone is excessively dry, it will turn on the pump and activate one or more of the solenoid valves controlling water flow to the nozzles in the appropriate AHU. Throughout the day, the fogging levels can increase or decrease as needed on any of the AHUs, with the VFD speeding up or slowing down to maintain the water pressure at 1000 psi.

This method of humidification is highly efficient, consuming much less energy compared to steam humidifiers.

Cost/Benefit Analysis:

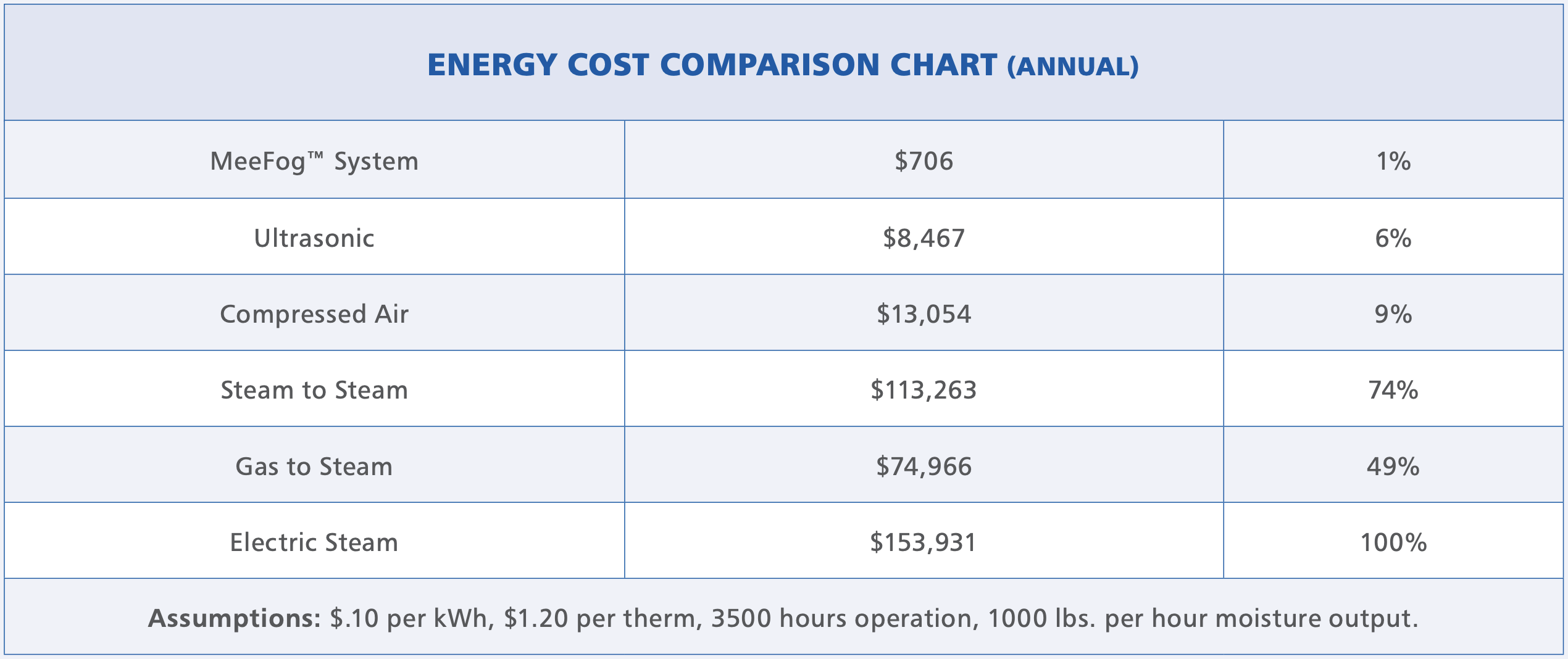

A Meefog system uses only about three percent of the electrical energy that a compressed-air or ultrasonic atomizer uses, and only one percent of the energy consumed by a steam humidification system. In addition, in buildings with a high heat load, the cooling effect of evaporation lowers the load on the air conditioning system.

Depending on relative humidity and temperature, Grand River Hospital starts using the fogging system and runs it until April. Goodall said that the hospital was “happy that the evaporative cooling effect during spring and fall periods saved a lot of chiller consumption, especially in the spring when the 4-5 degrees of cooling allowed the delay of starting the chiller plant with its electrical demand penalty.”

Learn More

Discover more successful Mee Industries building humidification systems installation projects and case studies