Magnets USA Optimizes Production Process with Humidification and Water Treatment from MeeFog

Humidification for Industry

Magnets USA Vinton, Virginia, USA

In 1990, Magnets USA founder Dale Turner recognized the potential for magnetic marketing and hasn’t looked back. Later joined by his brother Alan, the Turner brothers provide customers with superior, referral-boosting magnetic calendars, sports schedules and other marketing pieces. Based in the Roanoke Valley of Virginia, facility expansion and modernization required the opening of a new building. Management realized this needed to include a state-of-the-art humidification system to maintain building comfort for employees and to keep humidity at the desired level for on-site production processes.

Challenge:

Before the installation of the MeeFog humidification system, Magnets USA faced significant challenges with fluctuating humidity levels during winter. This inconsistency not only made indoor conditions uncomfortable for employees but also posed risks to production quality due to unsuitable humidity levels.

Solution:

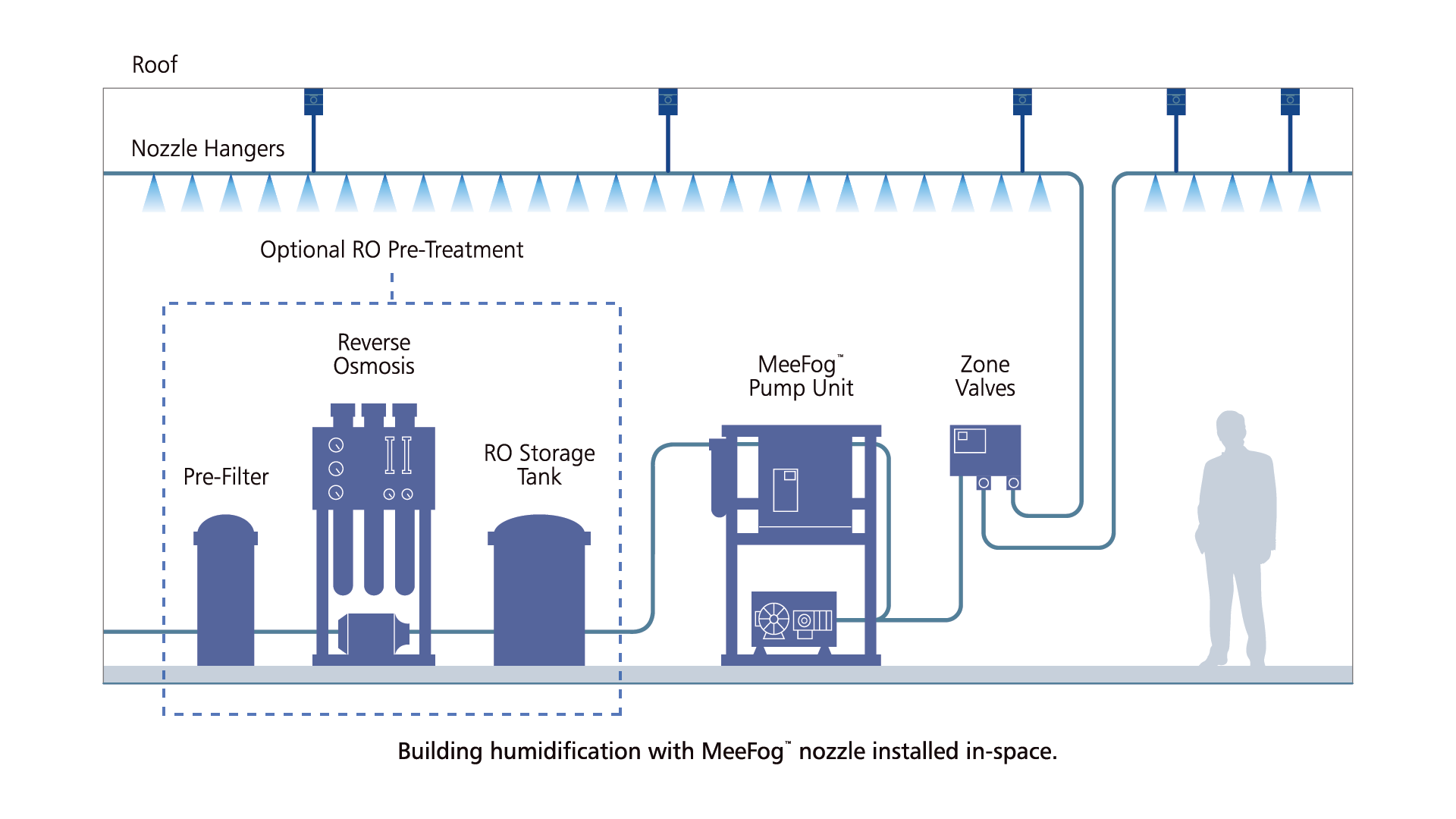

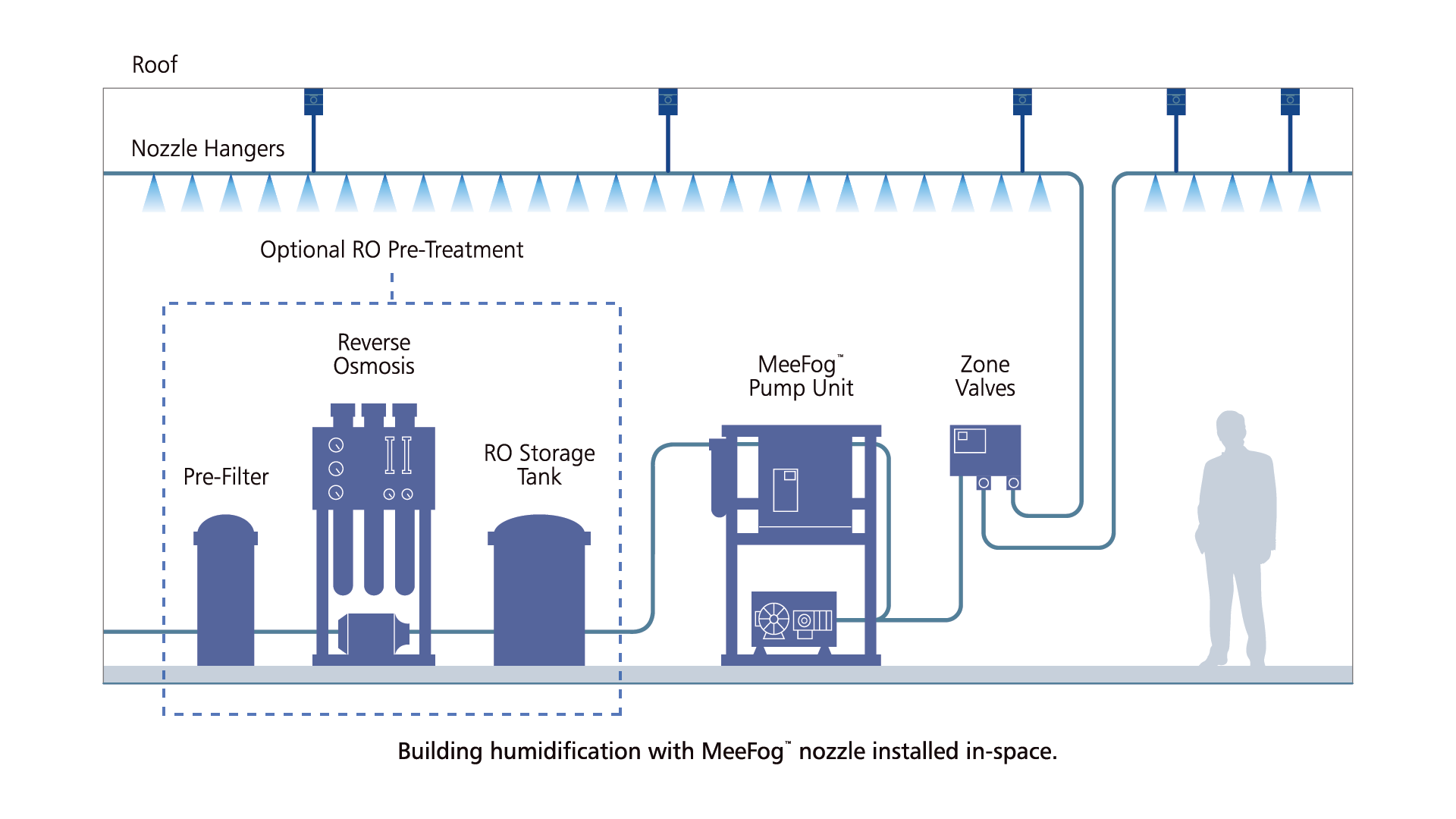

MeeFog Industries Inc. provided a comprehensive humidification solution tailored to Magnets USA’s needs. The system includes in-space humidification with nozzle lines strategically placed above the printing area and throughout the facility. This setup ensures consistent humidity levels, even when external doors are open or there are localized heat loads from machinery.

Strategy

Before the MeeFog system installation, relative humidity in the wintertime would drop to levels that make it uncomfortable for employees and unsuitable for production activities inside the building.

The company chose to install a MeeFog humidification system to keep humidity levels constant throughout the factory. Meefog nozzle lines were installed directly above the printing area. This in-Space humidification system helps maintain humidity when delivery bay doors are open; it also combats localized heat loads due to machinery, even when the area is supplied by air handlers.

Overhead tubes distribute the pressurized water to fogging nozzles distributed strategically in order to maintain tight control on humidity levels. The humidification system is supported by an energy saving MeeFog Reverse Osmosis (RO) water treatment system. Water purified with RO is recommended for MeeFog systems requiring air with low particulate concentrations.

Removing minerals and dissolved solids from supply water eliminates the accumulation of mineral dust and reduces routine maintenance. RO water can offer a Total Dissolved Solids (TDS) level of less than 10 PPM and eliminates the possibility of bacterial contamination and dusting issues. The RO system was designed to produce the needed flow even at cold water temperatures when RO membranes are less effective.

The MeeFog RO system has a water storage tank with UV treatment to eliminate bacterial growth in the stored water and is controlled by a PLC controller capable of communicating with the MeeFog control system. The fully integrated system ensures that the tank water level is monitored and circulation through the UV treatment is carried out especially during humidification system downtimes when the water is not being used.

Results

Dave Withers, Production Manager at Magnets USA, says the system has been performing flawlessly, maintaining the desired humidity levels and improving both employee comfort and production efficiency. “We have been surprised by how often the system has had to run,” Dave says.“Our initial estimates were that outside air would contain enough humidity for it not to be needed for a good part of the year. This has not proven to be the case. We have only had a few days this year when the humidity was high enough outside for the system not to run.“

Benefits using MeeFog Technology:

-

-

- Humidity maintained at optimum levels for employee comfort

- A fully conditioned production environment has positively impacted product quality and enhanced manufacturing processes

- Water purity level maintained with a Total Dissolved Solids (TDS) level of less than 10PPM

- Low maintenance costs

- Low energy usage

-

The system has been working flawlessly. Most importantly, our new fully conditioned production environment has positively impacted our product quality and manufacturing processes. – Dave Withers, Production Manager at Magnets USA.

Resources:

Learn more about how production companies achieve substantial energy savings and enhanced air quality with our innovative humidification solutions.

Contact Us:

Interested in improving your facility’s humidity control and boosting production efficiency? Request a quote and learn how our state-of-the-art humidification systems can meet your specific needs.