Smithsonian Lowers Energy Costs with MeeFog Humidification System

Humidification for Public Spaces

Smithsonian Institution Pennsy Collections and Support Center

Lining the National Mall in Washington, DC are some of the Smithsonian Institutions major museums — the Air and Space Museum, the American Indian Museum, the Natural History Museum, the American History Museum, all of which contain a fraction of what’s warehoused at the Pennsy Collections and Support Center. Within the Pennsy center, one can find rows of 20’ high shelving containing every imaginable type of artifact. The building also holds an extensive textile collection with floor to ceiling racks filled with 18th century pianos, as well as historic films, photos and documents. Since these artifacts are rare in nature, the building needed to follow strict environmental controls to preserve these treasures.

Challenge:

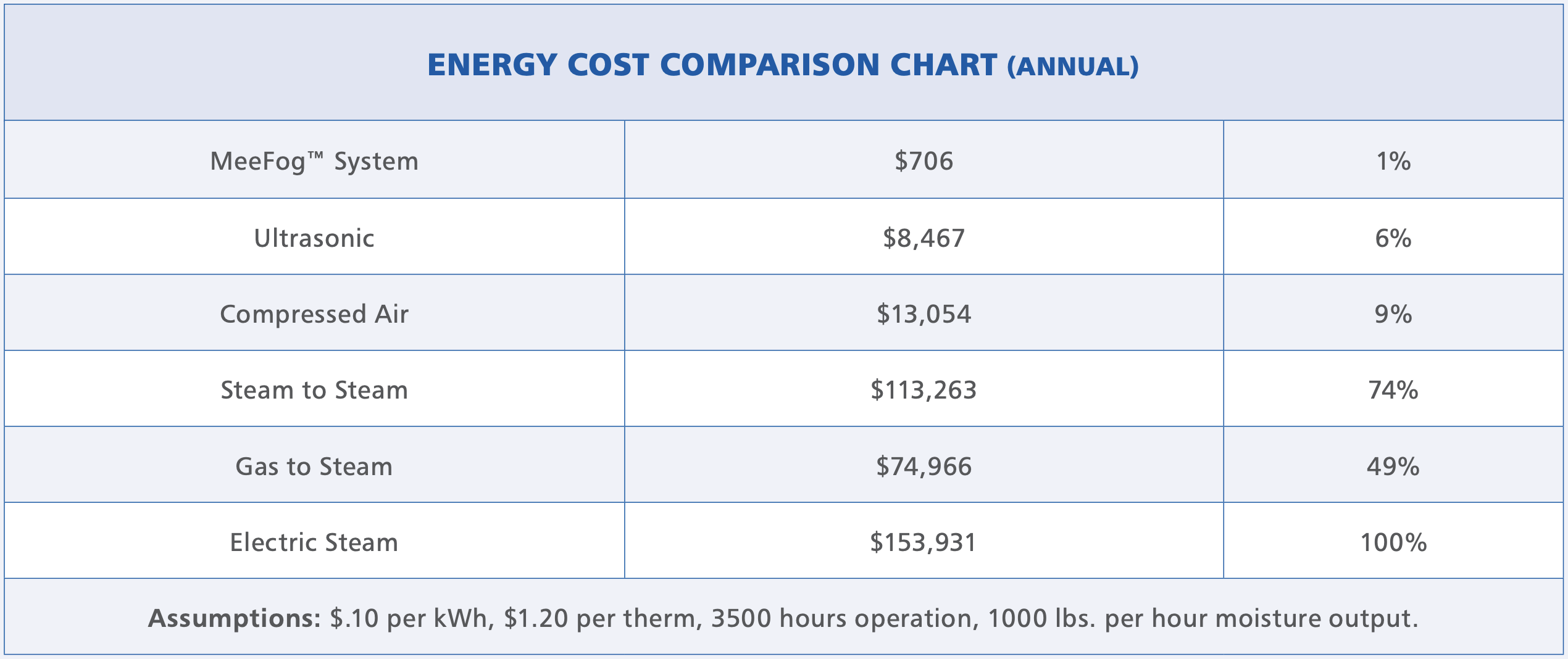

The facility needed a reliable and efficient system to maintain proper temperature and humidity levels across various climate zones, including areas requiring extreme conditions to preserve sensitive materials. Traditional systems like steam boilers were considered too costly and complex to maintain.

Solution:

A single high-pressure MeeFog humidification system designed to supply up to 540 lbs. per hour of moisture to fifteen separate duct mounted stainless steel humidification chambers. This system is energy-efficient, cost-effective, and easy to maintain, and allows for precise control of humidity throughout the facility.

Implementation

There are 29 separate roof mounted air handlers servicing the building. A single MeeFog system was designed to provide humidification to fifteen humidification chambers, each of which can be separately controlled to provide the right level of humidity for the area it serves.

One of the major challenges was creating a workable environmental control system for the building. Most buildings are designed for a limited range of climate zones. In this case there were offices, a café, meeting rooms and workshops that needed to be kept comfortable for humans. Within the archival portions, it was a whole different story. Most of the areas didn’t require any extreme temperatures or humidity levels, though one section did have to be kept at 52° and another at 26°. However, the rest of the warehouse the temperature and humidity must be tightly controlled. Don Posson was the managing principal engineer from Vanderweil for the project.

“The majority of the warehouse is one climate zone, with a standard humidity and temperature we dictate for the collections,” says Posson. “We have to avoid wide swings in the humidity. If it swings up and down the materials will expand and contract damaging the artifacts.”

The air in different areas did often need to be kept separate, for example some of the shops had dust collection systems that vented to outside collectors. Others had paint booths or soldering areas with Nederman snorkel exhaust units to remove the fumes. Some specialized labs required once-through air systems. In the end, Posson says there were at least 29 air handlers on the roof to maintain the air quality in different parts of the building.

“There were a lot of specialized areas, each with its own climate control,” he says. “We really wanted to keep the climate zones separated so there wouldn’t be any cross contamination.”

While there were a large number of air handlers, the building was able to get away with a single humidification system. Initially the warehouse was going to use a boiler, but this would have been too costly. Instead, they went with a MeeFog high pressure system which is much cheaper to operate and easier to maintain.

The MeeFog system is more energy-efficient, especially for a building that requires humidification throughout most of the year. We considered steam boilers but found them too costly. The MeeFog system keeps operational costs down while maintaining the necessary environmental controls. – Don Posson, Managing Principal Engineer, Vanderweil

Installation

The MeeFog system built for the Pennsy warehouse uses a single pump skid to pressurize the water and send it through 2400 feet of high pressure stainless tubing to fifteen separate duct mounted stainless steel humidification chambers. The pump can provide up to 540 lbs. of water per hour to arrays of impaction pin nozzles within those humidification chambers. The water passes through a .006″ orifice in the nozzle and then strikes the impaction pin, which splits the water stream into billions of minute droplets which rapidly evaporate in the airstream. Solenoid valves controlled by the building management system open or close as needed to control the water flow to the nozzles, providing the exact amount of humidification needed at that moment in time.

Client Benefits using MeeFog Technology:

- Able to provide humidity to a large number of air handlers with a single MeeFog system

- Significant energy savings compared to traditional steam humidifiers.

- Minimal maintenance required, with routine checks ensuring optimal performance.

Product Spotlight:

The Model Mee-3 is an economical, full-featured, industrial-quality, high-pressure fog pump unit. A variable frequency drive reduces pump wear and noise level, and allows operation of zones with few nozzles, without overheating the pump.

Resources:

Read more about how MeeFog systems provide precise environmental control to protect valuable artifacts and reduce operational costs

Contact Us:

Looking to enhance climate control in your facility? Ask us how MeeFog’s advanced humidification technology can meet your needs with easy retrofit and rapid installation.