Pall Life Sciences Enhances Clean Room Efficiency

Clean Rooms

Pall Life Sciences

Pall Corporation is a leading global provider of filtration, purification, and separation technologies to the diverse and rapidly expanding life sciences market. To support their growing product offerings, Pall needed to expand their clean room manufacturing space and sought an energy-efficient humidification solution. Chuck Carpenter, facilities manager and construction coordinator for the addition, immediately started looking for ways to design an energy efficient clean room that would serve the company’s manufacturing needs for years to come.

An Energy-Efficient Solution:

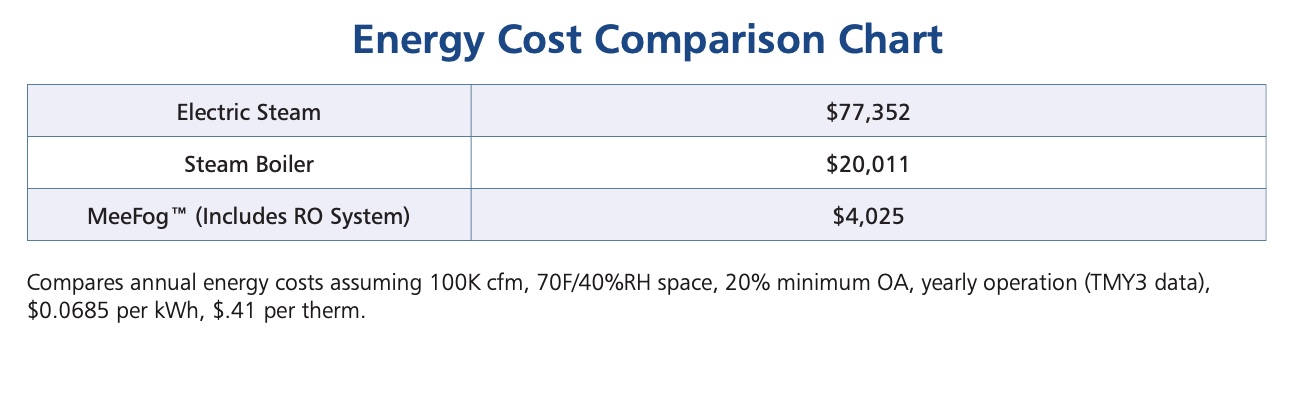

The current facilities incorporate multiple clean room manufacturing spaces, and Pall has experimented with various humidification methods but their experiences with electric steam and ultrasonic techniques have been unsatisfactory due to high operating costs and demanding maintenance requirements. Seeking a more efficient solution, Chuck enlisted the expertise of Mee Fog to design an energy-efficient system.

To preserve the integrity of the clean room envelope, positive pressure has to be maintained in the room at all times. To accomplish this, large amounts of outside air are required to off set the exhaust and room leakage. The large air flows must have tight temperature and humidity control, and doing so in a budget friendly way was very important.

Mee Fog agreed to assist them in designing a humidification system that would provide the humidity control they desired in an energy efficient manner. The new clean room space has a custom roof mounted air handler rated at 45,000 cfm. The unit has 35,000 cfm of recirculation and 10,000 cfm of air that passes through heating and cooling coils. The Mee Fog nozzles are located in the 35,000 cfm section and humidify the recirculation air stream. A single high pressure Mee Fog pump provides 1000 psi water to the nozzle headers. System capacity is controlled by controlling the Mee Fog pump speed, which modulates the amount of water that is pumped to the nozzle headers. The system is controlled by the building control system.

Challenge:

The company required a new clean room with tight temperature and humidity control to maintain positive pressure and ensure the integrity of the clean room envelope. Previous methods, such as electric steam and ultrasonic humidifiers, proved unsatisfactory due to high operating costs and demanding maintenance.

Solution:

MeeFog designed a high-pressure humidification system for clean room recirculation tailored to Pall Life Sciences’ needs. The system includes a custom roof-mounted air handler rated at 45,000 cfm, with 35,000 cfm of recirculation air and 10,000 cfm passing through heating and cooling coils. MeeFog nozzles are installed in the recirculation section to efficiently humidify the air stream, with a single high-pressure pump providing 1000 psi water to the nozzle headers.

Client Benefits using MeeFog Technology:

- Enhanced Humidity Control

- Reduced Maintenance

- Energy Efficiency

- Tighter Control

The system controls the room humidity levels perfectly. I have had to do very little maintenance on this system and it integrated into the building management system very well. I wouldn’t change anything on the MeeFog system. — Chuck Carpenter, Facilities Manager, Pall Life Sciences

Resources:

Learn more about how MeeFog’s high-pressure fogging systems can benefit your facility!

Contact Us:

Looking to enhance your clean room’s efficiency with advanced humidification systems?