MeeFog Adds 64MW of Power Augmentation to Mexican Power Plant

Gas Turbine Wet Compression

Tuxpan Power Plant, Mexico

The Tuxpan III and IV combined cycle power plant is operated by Global Power Generation (GPG), which is a company of the Naturgy group and a significant player in Mexico’s energy sector. The plant is located northeast of Mexico City in Veracruz, 10 meters above sea level and approximately one kilometer from the Gulf of Mexico. The facility is known for its efficiency and reliability in power generation, and has played a crucial role in meeting the region’s growing energy demand and supporting the economic and social development of the area.

Challenges Faced:

With new energy regulations in Mexico permitting power to be sold directly to end users, providers looking to capitalize on this market opportunity must deliver the maximum amount of electricity at the lowest possible cost. The plant’s MHPS 501F gas turbines could not achieve the desired output under this new competitive landscape.

Solution:

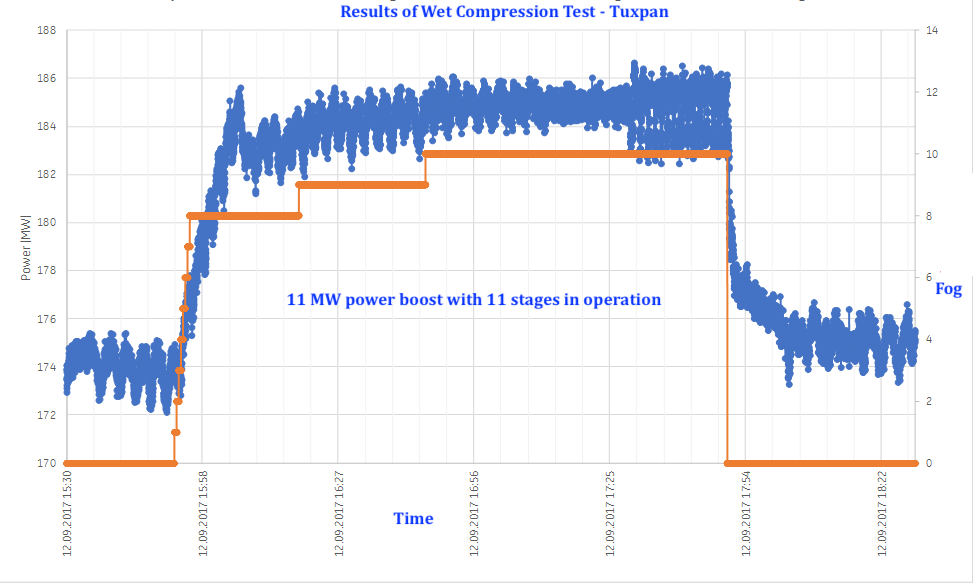

MeeFog Industries equipped the Tuxpan III and IV power plant with wet compression systems for its four MHPS 501F gas turbines. This installation boosted the output per turbine from 164 MW to 180 MW, adding a total of 64 MW to the plant’s capacity.

Installation Specifications:

The Tuxpan combined cycle plant had media type evaporative coolers installed on each of the Mitsubishi Hitachi Power Systems (MHPS) 501F gas turbines. The MeeFog systems were installed downstream of the existing evaporative media. The nozzle manifolds provide a few degrees of evaporative cooling because the media-type evaporative coolers are not 100% effective, and additional wet compression spray with a flow rate equal to 1% of the air mass flow of the gas turbines. Mee Industries provided turnkey installation of the wet compression systems including connection to water and electrical supplies. General Electric provided controls modifications with support from Mee’s engineers.

The Tuxpan Power Plant consists of two identical power blocks, each equipped with two MHPS 501F gas turbines, two heat recovery boilers, and one steam turbine. Each block has a power output of approximately 500 MW. As part of the project, two fog pump skids were installed at each gas turbine along with fog nozzle manifolds in the inlet duct. These systems are designed to provide 14 equal stages of fog spray output, with each stage comprising 71 fog nozzles, totaling 994 fog nozzles.

Results:

The 14 stages of wet compression are tied into the gas turbine controls so the grid authority has control over the amount of power augmentation via the automatic generation signal. This allows for seamless control of the amount of power augmentation above base load as required by the grid authority. Prior to the installation, the MHPS 501F turbines with evaporative coolers produced 164.2 MW each. This was increased to 180 MW with Wet Compression. The systems gave the plant a total of 64 MW of additional power to sell into the Mexican grid.

Client Benefits using MeeFog Technology:

- Plant power production boosted by 64MW via wet compression

- Increased efficiency

- Lower emissions

The system was designed to produce 15.5 MW of power augmentation per turbine. However, the actual results exceeded this estimate. — Rafael Garcia, Technical Consultant, GARPE, S.A. de C.V. of Mexico

Resources:

Discover how our wet compression systems can boost performance and lower emissions.

Contact Us:

Ready to enhance your power plant’s efficiency with MeeFog’s wet compression systems?