Boost of 28 MW on two Siemens SGT-5000FD2 GTs Using Wet Compression

Fog Cooling For Gas Turbines & Heat Exchangers

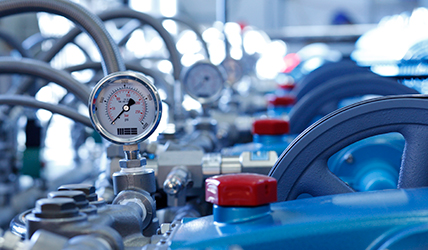

MeeFog wet compression systems were fitted onto two Siemens SGT-5000FD2 gas turbines in the state of Durango in the north-west of Mexico. The fog systems raised the output of each turbine from 157 MW to 171 MW for a total power boost of 28 MW. The fog systems cost much less than chillers or other power augmentation systems and far less than adding new turbines.

The systems have operated for more than five years now with no reported damage to the gas turbines. MeeFog wet compression systems use the same pumps and nozzles as our evaporative cooling fog systems. The super-small droplet size ensures there is no erosion of the compressor blades.

Project Conditions:

Location: Norte Durango, Mexico

Model: Seimens SGT-5000FD2

Elevation: 6,076 ft ASL

Mee’s scope of work: Removal of existing nozzle lines, supply of new MeeFog pump skid, nozzle manifolds, supervision of installation and commissioning.

Fog System Design:

MeeFog™ nozzle count: 858

Operating Pressure: 2,000 psi

Nozzle flow rate: 0.08 gpm

Total Skid Flow: 68.6 gpm

Max Power Requirement: 82.1 kW

Fogging Stages: 11

Learn More

Want to learn more about successful Meefog systems installation projects and case studies?