Jamieson Ranch Vineyards Saves on Topping Costs by Improving Humidification

Agriculture

Jamieson Ranch Vineyards is the southernmost winery in the Napa Valley, one of the world’s foremost winemaking regions. The estate’s more than 300 acres of gently rolling hills and terraced vineyards benefit from the cooling fog and breezes from the nearby San Pablo Bay, climatic conditions that favor the production of exceptional Pinot Noir and Chardonnay.

The unique architecture of Jamieson Ranch Vineyards is reminiscent of a western mountain lodge, replete with soaring ceilings, seating around a cozy fireplace, an observation gallery overlooking the barrel room and production area, and a spectacular wraparound veranda that affords sweeping views of the Napa Valley and San Pablo Bay.

The Challenge:

With a lack of space on site, Jamieson Ranch Vineyards’ rapid expansion forced it to convert an old bottling facility into a barrel room. By doing so, it had to address low humidity in the new space. This led to barrels drying out during the ageing process and too much wine evaporating.

The Solution:

Adding a MeeFog’s agricultural humidification system kept empty barrels from drying out and greatly reduced the need for topping due to evaporative losses. In addition, the state-of-the-art MeeFog agricultural humidification system slashed maintenance and energy costs compared to older humidification systems the company employs in its other barrel rooms.

Challenges/Specifications in Installing Meefog Systems’ Humidification for Agriculture:

The company owned two barrel rooms. But expansion necessitated that it open an additional barrel room in a 9,800 square foot building formerly used as a bottling warehouse. However, this space was far from ideal from a wine storage perspective. The very dry air caused problems.

Without humidity control, the wood dries out which then allows some of the wine to soak through the wood and evaporate. To make matters worse, drying wood shrinks. This loosens the seals between the staves which further increases wine losses. With some Jamieson wine selling for $780 a bottle, such losses are costly. Jamieson Ranch Vineyards realized that it needed a top-notch humidification system in order to maintain the right moisture level in its new barrel room.

The Installation of Meefog’s Agricultural Humidification Fogging System:

In the facility’s older barrel rooms, compressed air humidification systems are employed. These systems comprise compressed air units situated on the floor with misters placed right in front of the air jet. However, such systems have proven expensive to operate and don’t distribute humid air evenly across the facility. In particular, the top half of the barrel room often remains dryer than the bottom half. “Cellar masters at Cakebread Cellars and Silver Oak Cellars said they had been using a fog based system from Mee Industries to address similar issues to ours,” said John Maguire, Cellar Master, Jamieson Ranch Vineyards.

When he compared the various systems available, he found that a MeeFog agricultural humidification system would provide more comprehensive and uniform humidity control. In addition, it would be much cheaper to operate than a compressed air system and more reliable. Based on an electricity rate of 12 cents per kWh and 136.6 pounds per hour of moisture output, MeeFog’s agricultural humidification system consumes $80 per year in energy costs for 1500 hours per year of operation compared with $1492 per year for a compressed air system.

“The compressed air systems in our older barrel rooms don’t have nearly as many nozzles and have to run a lot longer in an effort to keep humidity sufficiently high,” said Maguire. “Our MeeFog agricultural humidification system has far more nozzles which are located above the barrels. It’s a nicer and cleaner system which distributes the mist far more evenly while only needing to run a fraction of the time.”

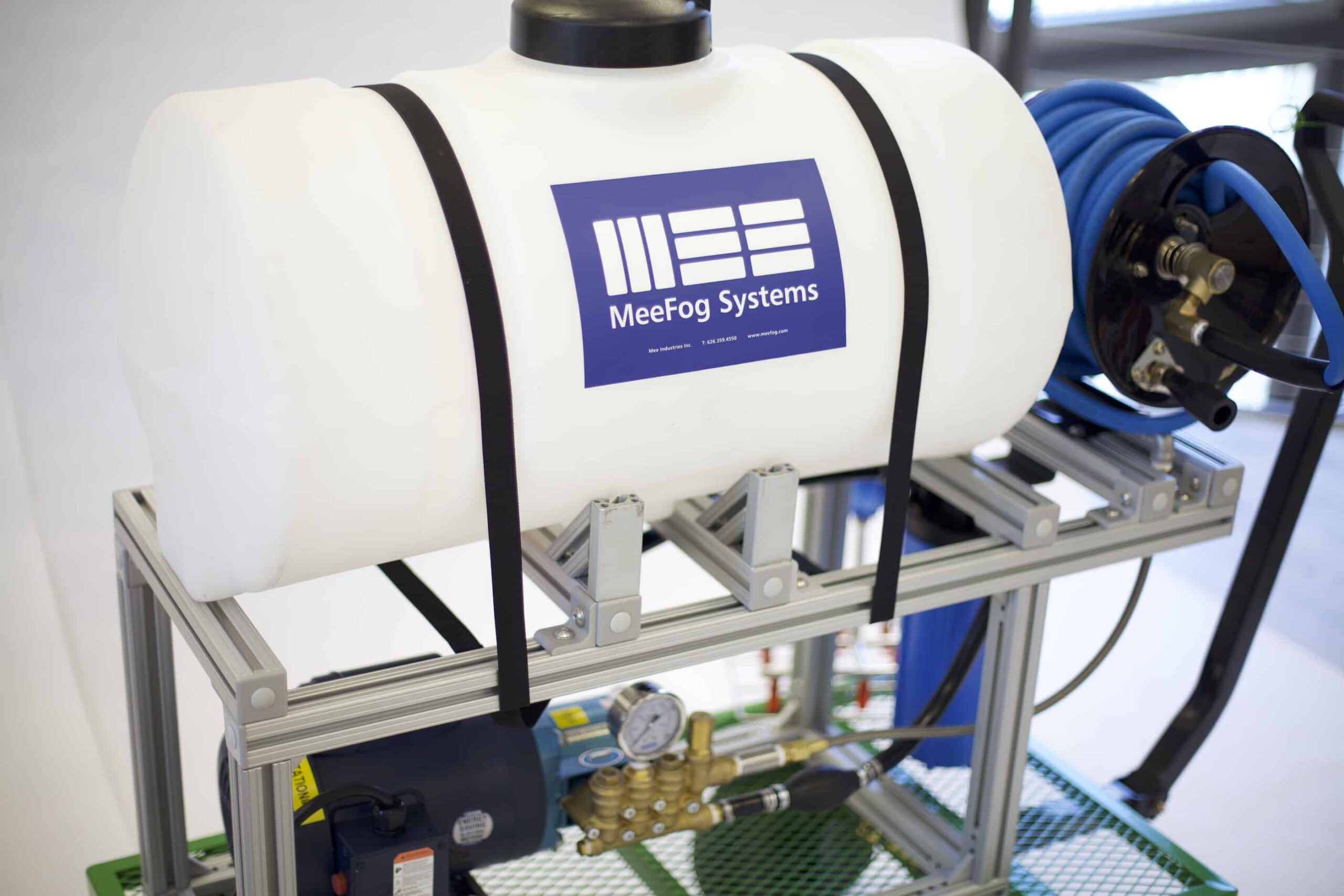

The MeeFog humidification system sits on a small pump skid uses 0.27 gpm of water which is pressurized to 1000 psi. The stainless steel fog nozzles are installed near the ceiling of the barrel room right above the barrels. The fog then drifts down evenly over the barrels, preventing them from drying out. To increase efficiency, the system uses a network of sensors to measure humidity throughout the barrel room. When humidity drops below 80%, the fog system turns on automatically and shuts off as soon as it achieves the desired level.

The MeeFog agricultural humidification fogging system sits on a small pump skid uses 0.27 gpm of water which is pressurized to 1000 psi. The stainless steel fog nozzles are installed near the ceiling of the barrel room right above the barrels. The fog then drifts down evenly over the barrels, preventing them from drying out. To increase efficiency, the system uses a network of sensors to measure humidity throughout the barrel room. When humidity drops below 80%, the fog system turns on automatically and shuts off as soon as it achieves the desired level.

“The MeeFog system has reduced topping and keeps our barrels tighter by maintaining humidity at 80%. In addition, our empty barrels no longer dry out which helps maintain their integrity,” said Maguire. “We expect our energy savings to be considerable compared to our older compressed air systems.”

Learn More About Meefog’s Fogging and Humidification for Agriculture

Discover more projects and case studies documenting successful installations of Meefog’s: agricultural humidification system.

Request a Quote

Find out how you can apply Meefog’s Fogging System for your agricultural humidification needs here by filling out this form: