Oil Refinery Increases Output with Inlet Air Cooling

BlogIn recent years, the number of oil refineries has dropped by half, so to meet growing demand for fuel, existing refineries have added capacity. But with increased emissions regulations, any expansion is closely scrutinized, so refineries must continually find ways to lower their energy usage and reduce their environmental impact.

The Challenge

An L.A. based oil refinery uses a gas turbine to convert oil into electricity. Increased demand due to plant expansion exceeded the generator’s output on hot days. On hot days, air is less dense, causing gas turbine output to drop by as much as 5 MW.

The Solution

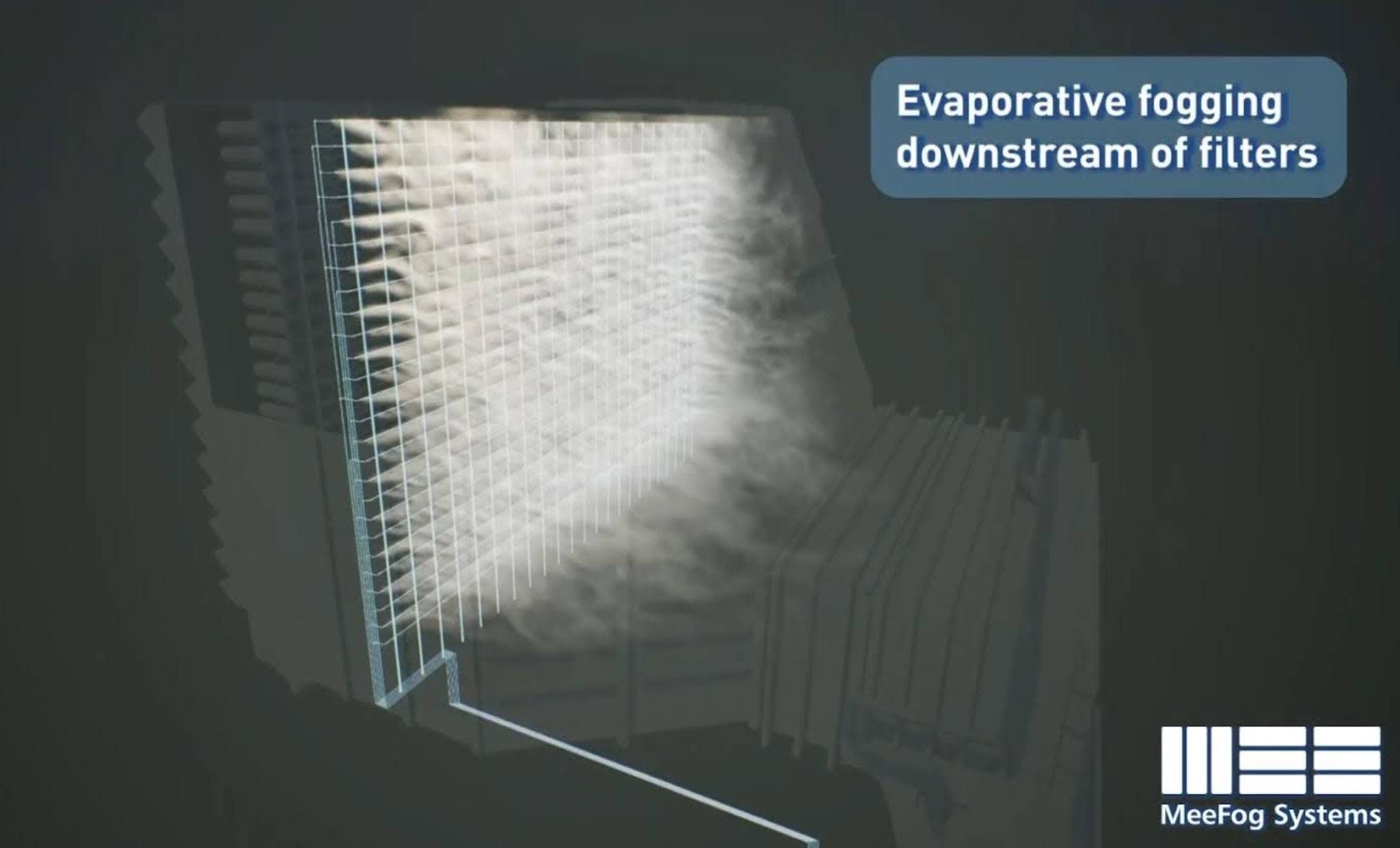

Mee Industries installed a fog cooling system to help maintain optimum gas turbine performance, even on hot days. An array of 429 fogging nozzles were installed just downstream of the air filter. The system has 11 operating stages providing up to 30 degrees of cooling, so the inlet temperature can be controlled within a few degrees.

“During the performance tests, we dropped from 100 degrees to 70 degrees F at the inlet… We gained 5 MW which brought us back up to the nominal rating.” – Project Manager